Best quality Low Melt Pouch - Batch Inclusion Bags – Zonpak

Best quality Low Melt Pouch - Batch Inclusion Bags – Zonpak Detail:

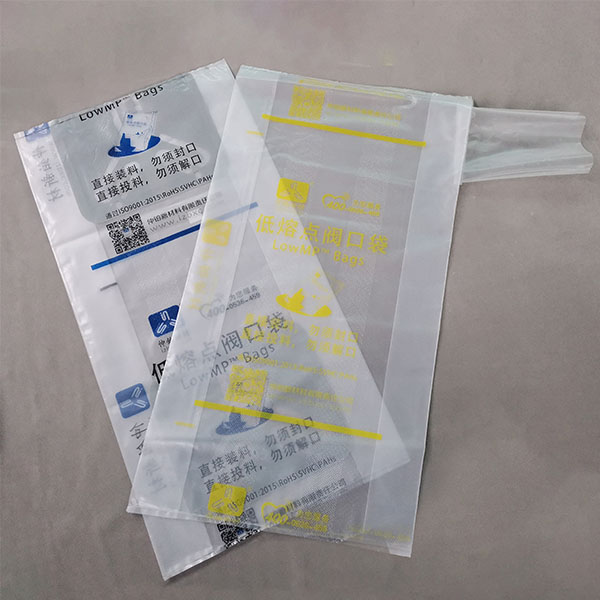

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into an internal mixer. The bags can easily melt and fully disperse into the compounds as a minor ingredient.

Using batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and increase work efficiency. Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirements.

|

Technical Standards |

|

| Melting point available | 72, 85, 105 deg. C |

| Physical properties | |

| Tensile strength | ≥12MPa |

| Elongation at break | ≥300% |

| Appearance | |

| There is no bubble, hole and poor plasticization. Hot sealing line is flat and smooth without weak seal. | |

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Best quality Low Melt Pouch - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Jersey , Malaysia , Irish , With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our goods, make sure you contact us now. We're looking forward to hearing from you soon.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!