China Cheap price Low Melting EVA Bags - Low Melt Batch Inclusion Bags – Zonpak

China Cheap price Low Melting EVA Bags - Low Melt Batch Inclusion Bags – Zonpak Detail:

With particular low melting points and good compatibility with rubber and plastics, the EVA batch inclusion bags are specially designed for the rubber or plastic compounding process. The bags are used to pre-weigh and temporarily store the rubber ingredients and additives, and they can be direct thrown into a banbury mixer during compounding process. Using low melting batch inclusion bags can help ensure accurater adding of chemicals, keep the mixing area clean, minimizes the worker exposure to harmful materials and increases the compounding efficiency.

PROPERTIES:

1. Different melting points (from 70 to 110 deg. C) are available as required.

2. Good physical strength, such as high tensile strength, impact strength, puncture resistance, flexibility, and rubber-like elasticity.

3. Excellent chemical stability, nontoxic, good environmental stress cracking resistance, weather resistance and compatibility with most rubber e.g. NR, BR, SBR, SSBR.

APPLICATIONS:

Various rubber chemicals and additives (e.g. carbon black, silica, anti-aging agent, accelerator, curing agent and rubber process oil

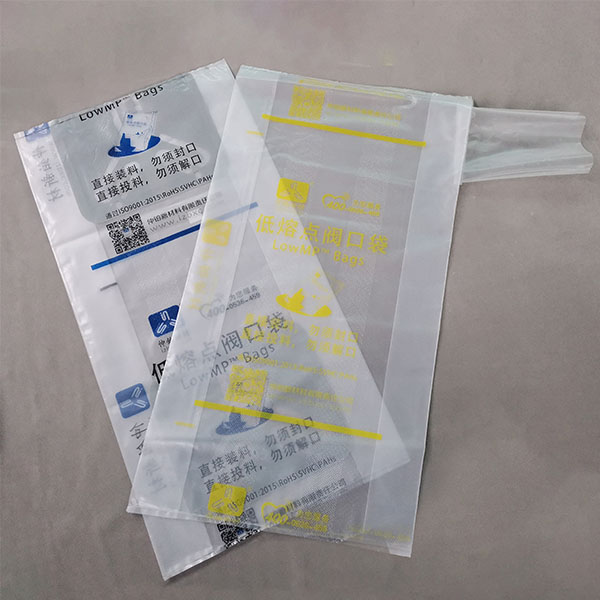

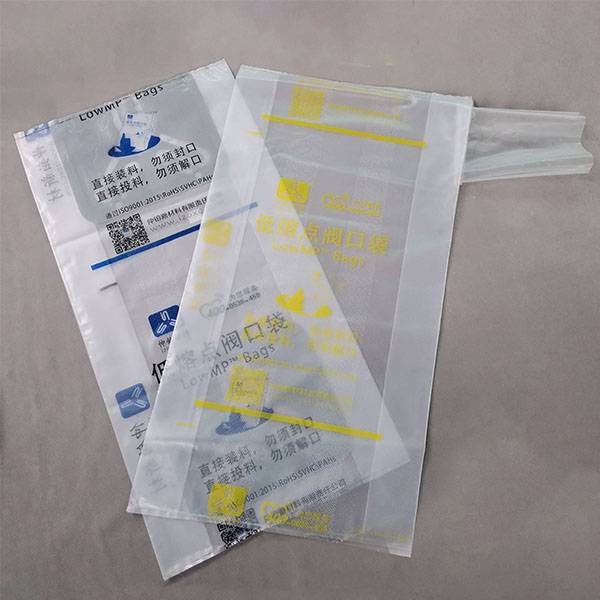

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for China Cheap price Low Melting EVA Bags - Low Melt Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Estonia , South Korea , Iraq , Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.