China wholesale Batch Inclusion Bags - Low Melt Bags for Plastic Compounding – Zonpak

China wholesale Batch Inclusion Bags - Low Melt Bags for Plastic Compounding – Zonpak Detail:

ZonpakTM low melt bags are used to pack compounding ingredients (e.g. process oil and powder additives) in plastic compounding and mixing process. Due to the property of low melting point and good compatibility with plastics, the bags together with the packed additives and chemicals can be direct put into a mixer, so it can provide cleaner work environment and accurate adding of additives. Using the bags can help plants get uniform compounds while saving additives and time.

Melting point, size and color can be customized according to the customer’s specific application requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

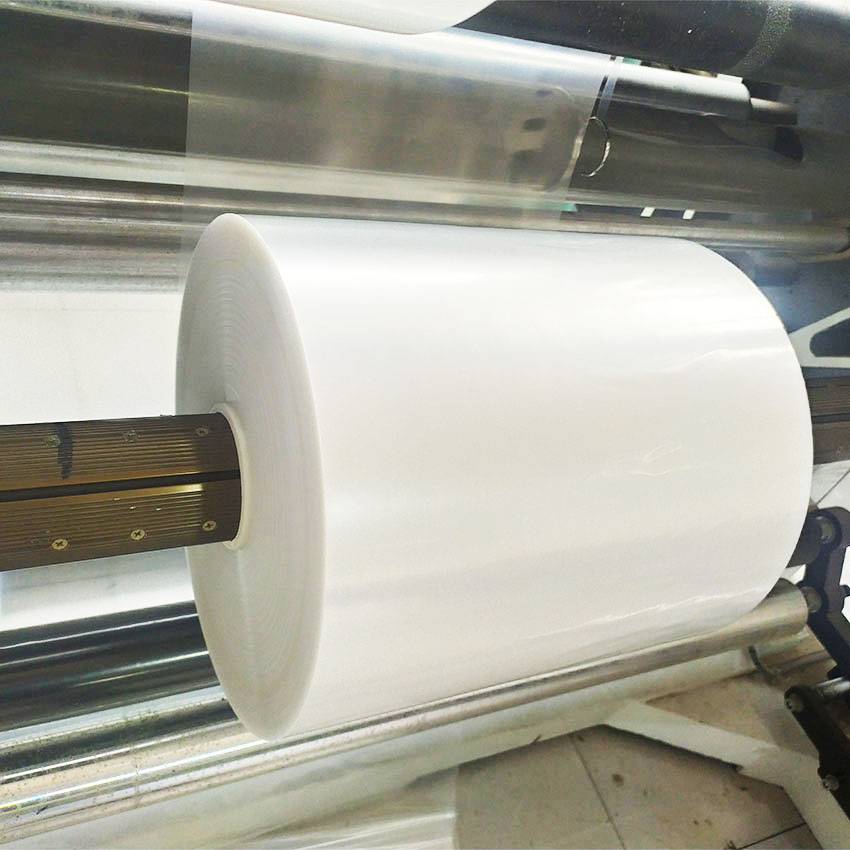

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for China wholesale Batch Inclusion Bags - Low Melt Bags for Plastic Compounding – Zonpak, The product will supply to all over the world, such as: Amsterdam , India , Algeria , We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.