Chinese Professional Low Melt Bags For Rubber Additives - Low Melting Point Plastic Bags – Zonpak

Chinese Professional Low Melt Bags For Rubber Additives - Low Melting Point Plastic Bags – Zonpak Detail:

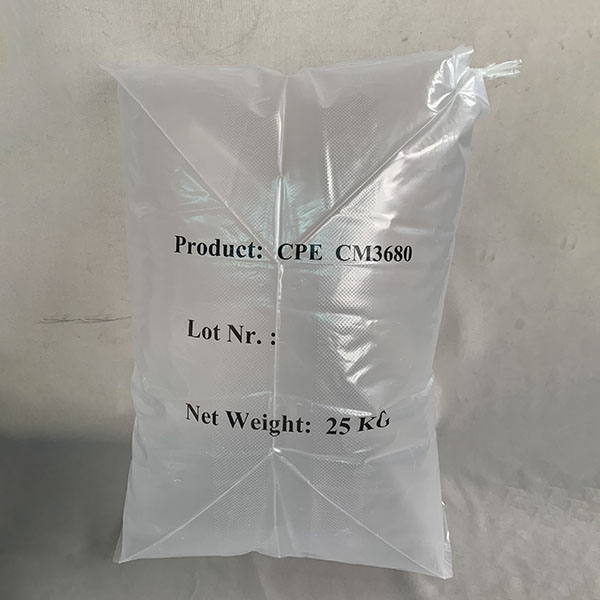

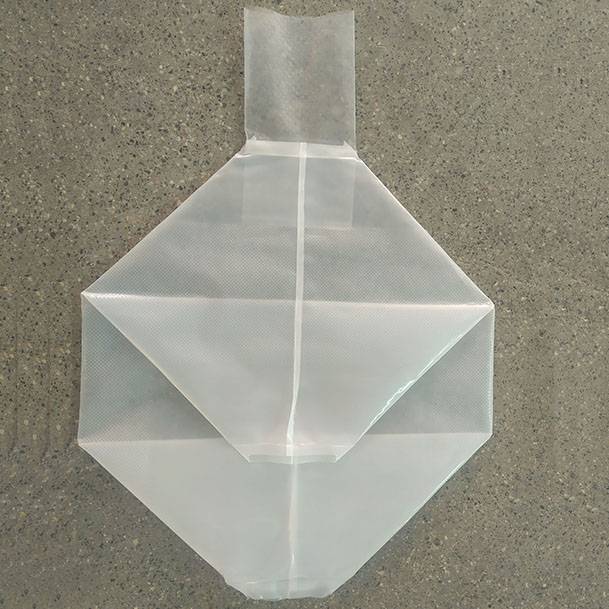

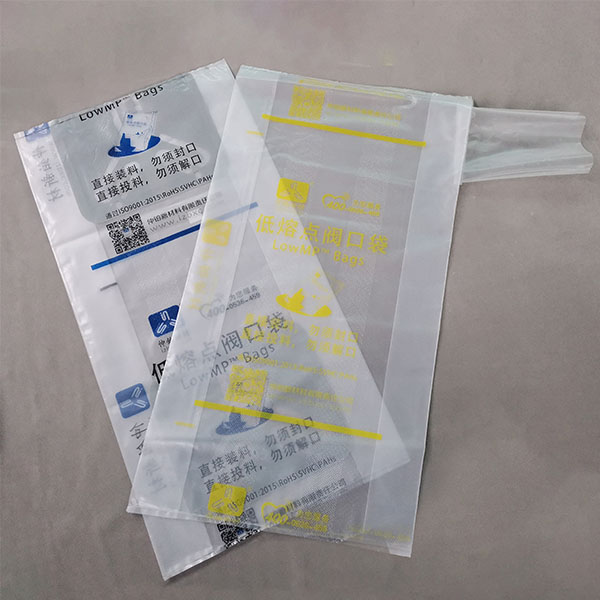

ZonpakTM low melting point plastic bags are made from EVA (Ethylene Vinyl Acetate), and are mainly used to pack compounding ingredients in tire and rubber industries. Due to the property of low melting point and good compatibility with rubber, the bags together with the additives contained can be direct put into an internal mixer and fully disperse into the rubber as a minor effective ingredient, so it can provide accurate dosing of additives and clean mixing area. Using the bags can help get uniform rubber compounds while save additives and time.

Melting point, size and color can be customized according to the customer’s application requirement.

APPLICATIONS:

- carbon black, silica (white carbon black), titanium dioxide, anti-aging agent, accelerator, curing agent and rubber process oil

OPTIONS:

- colour, printing, bag tie

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 150-1200 mm

- Bag length: 200-1500mm

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Chinese Professional Low Melt Bags For Rubber Additives - Low Melting Point Plastic Bags – Zonpak, The product will supply to all over the world, such as: Southampton , Bangalore , Swedish , With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.