Chinese Professional Low Melt VFFS Film - EVA Packaging Film for Rubber Cure Accelerator – Zonpak

Chinese Professional Low Melt VFFS Film - EVA Packaging Film for Rubber Cure Accelerator – Zonpak Detail:

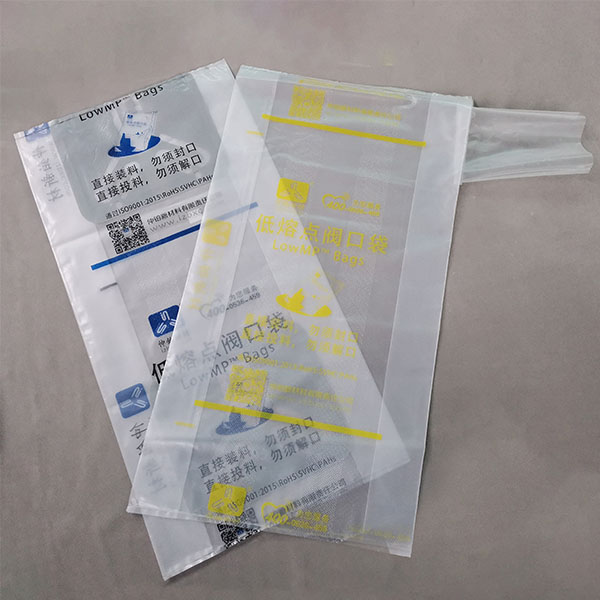

ZonpakTM EVA packaging film is a special kind of plastic film with particular low melting point mainly used for packing rubber chemicals. Cure accelerator is an important chemical used in rubber compounding and mixing, but only a little amount is needed for each batch. Rubber chemical suppliers can use this packaging film with an automatic form-fill-seal machine to make little bags of cure accelerate for the users’ convenience. Owing to the film’s low melting point and good compatibility with rubber, these uniform little bags can be direct put into a banbury mixer in the rubber mixing process, the bags will melt and fully disperse into the compounds as a minor ingredient.

OPTIONS:

- single wound sheeting, center folded or tube form, colour, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-200 micron

- Film width: 200-1200 mm

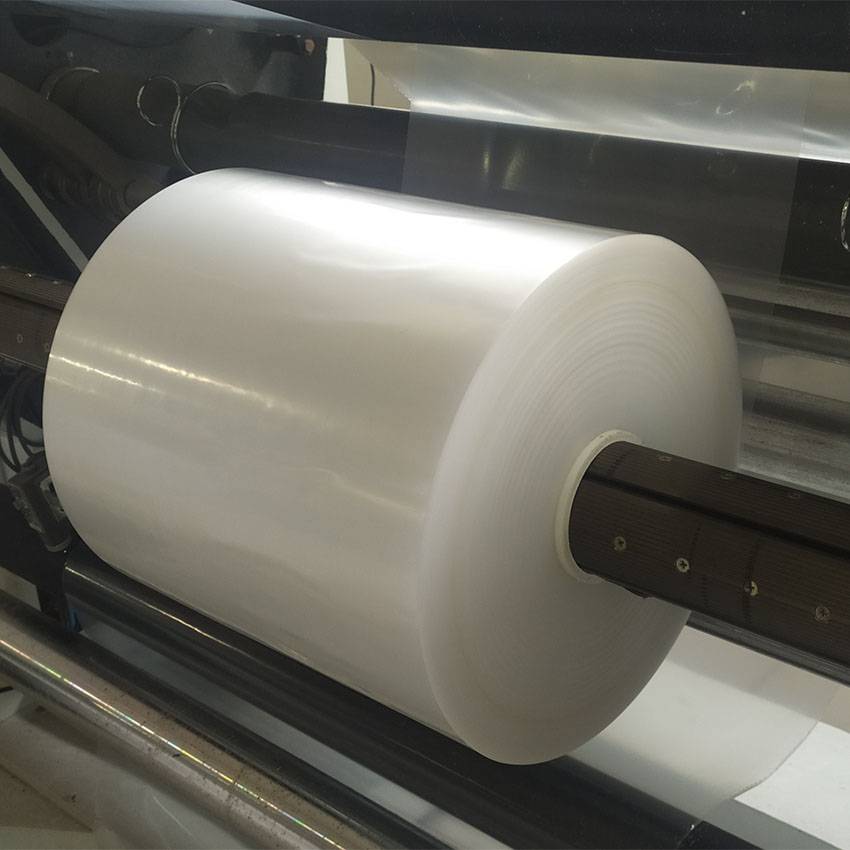

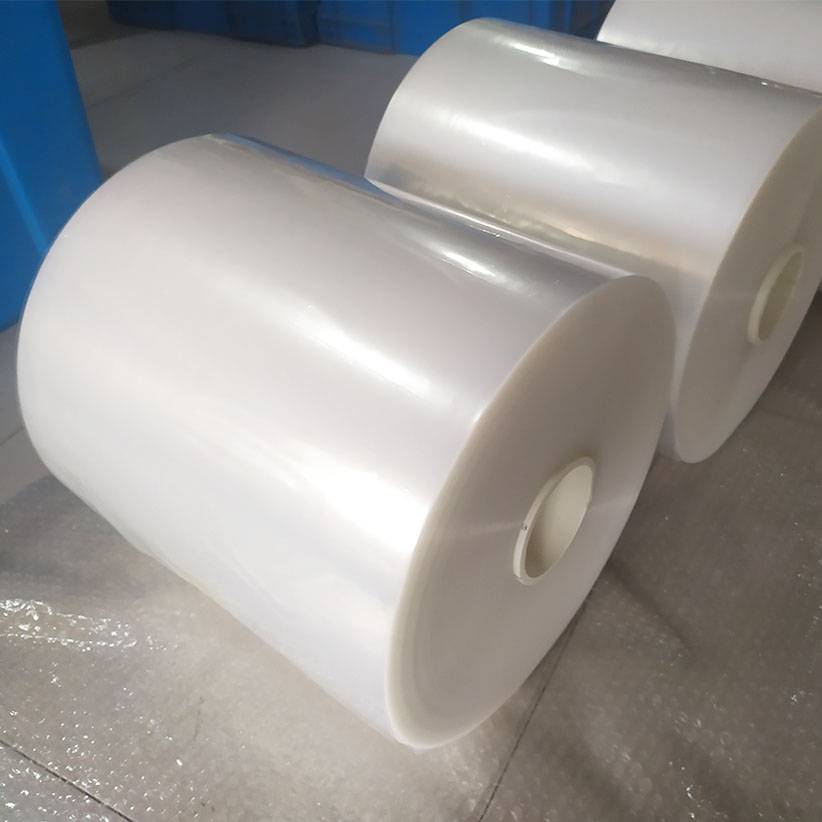

Product detail pictures:

Related Product Guide:

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Chinese Professional Low Melt VFFS Film - EVA Packaging Film for Rubber Cure Accelerator – Zonpak, The product will supply to all over the world, such as: Poland , Congo , Orlando , Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!