Free sample for Micro Perforated Film Packaging - EVA Batch Inclusion Film – Zonpak

Free sample for Micro Perforated Film Packaging - EVA Batch Inclusion Film – Zonpak Detail:

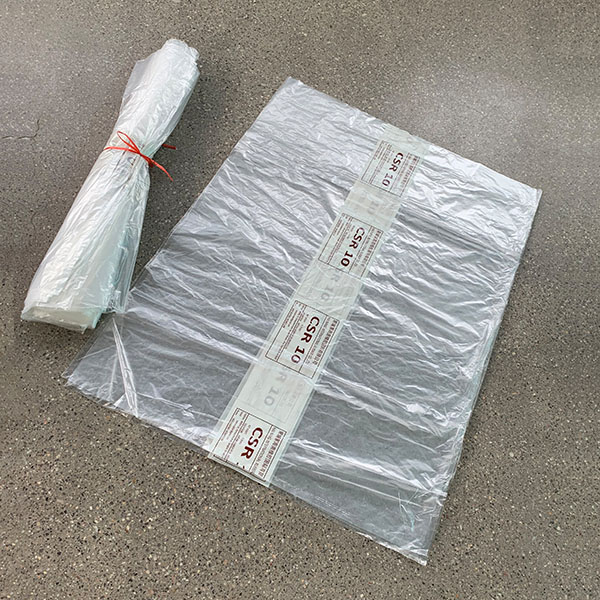

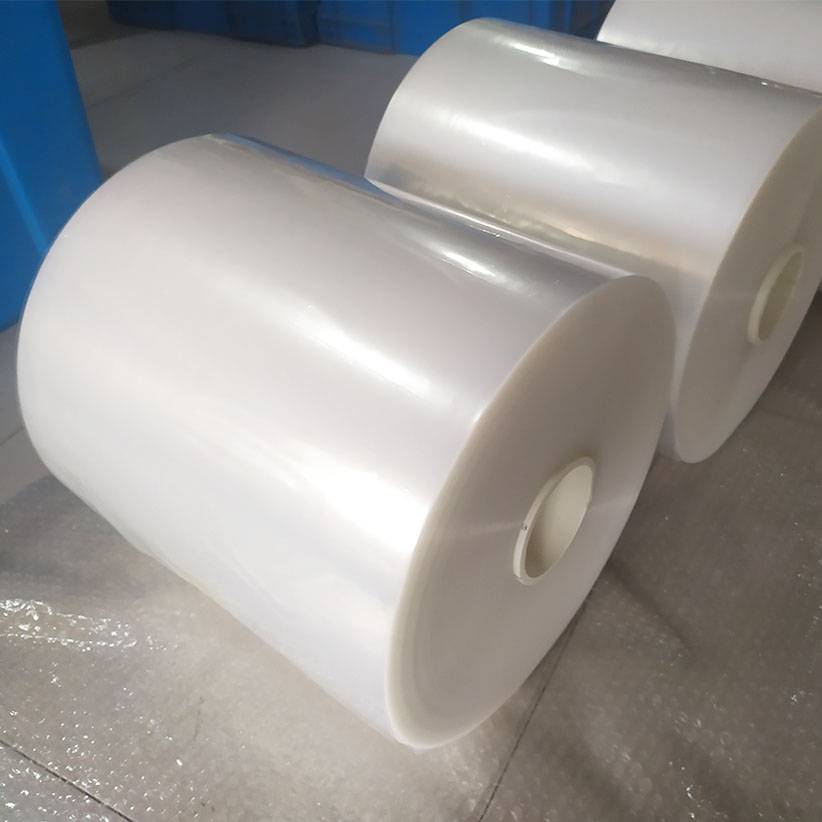

ZonpakTM EVA batch inclusion film is a special kind of packaging film with specific low melting point. It is mainly used on the automatic FFS (form-fill-seal) packing machine to make little packages (100g-5000g) of rubber additives or chemicals. Due to the film’s property of low melting point and good compatibility with rubber and plastic, these little packages can be direct put into an internal mixer during mixing process, and the bags will melt and fully disperse into the mix as an effective ingredient. It brings convenience to the material users and eliminates packaging waste disposal.

Different melting points are available as customers required. Stable chemical properties and high physical strength of the film make it suitable for most rubber chemicals and automatic packaging machines.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for Free sample for Micro Perforated Film Packaging - EVA Batch Inclusion Film – Zonpak, The product will supply to all over the world, such as: Atlanta , Australia , Serbia , Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.