New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak

New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak Detail:

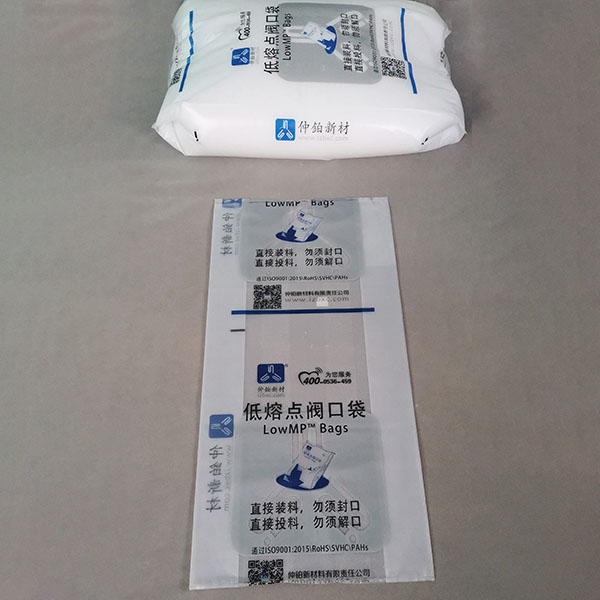

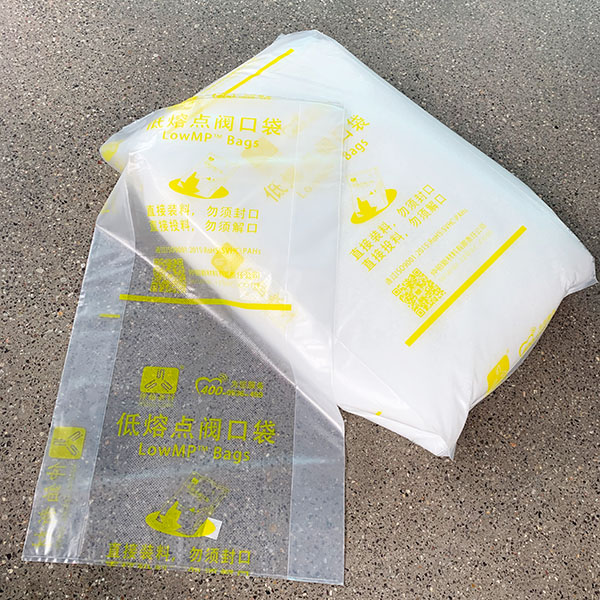

Low melt valve bags are specially designed for the industrial packaging of rubber and plastic additives. Using the low melt valve bags with an automatic filling machine, material suppliers can make standard packages e.g. 5kg, 10kg, 20kg and 25kg which can be direct put into an internal mixer by the material users. The bags will melt and fully disperse in the rubber or plastic mixture as a minor effective ingredient in the compounding and mixing process. So it is more popular than paper bags.

BENEFITS:

- No fly loss of materials

- Improved packing efficiency

- Easy stacking and palletizing

- Assure accurate adding of materials

- Cleaner work environment

- No packaging waste left

APPLICATIONS:

- rubber and plastic pellet or powder, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1500 mm

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak, The product will supply to all over the world, such as: Iceland , Lesotho , Tanzania , Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.