Batch Inclusion Matumba

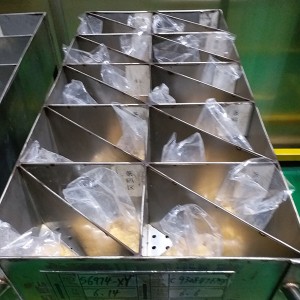

Gulumatumba ophatikizidwaadapangidwa kuti azipaka zinthu zophatikizira mu rabala kapena kusanganikirana kwa pulasitiki kuti apititse patsogolo kufanana kwa batch. Matumba okhala ndi malo osungunuka osiyanasiyana ndi oyenera kusakanikirana kosiyana. Chifukwa cha kusungunuka kwawo kochepa komanso kumagwirizana bwino ndi mphira, matumba pamodzi ndi mankhwala kapena zowonjezera mkati zimatha kuikidwa mwachindunji mu chosakaniza chamkati. Matumbawo amatha kusungunuka mosavuta ndikubalalika kwathunthu mumaguluwo ngati chophatikizira chaching'ono.

Kugwiritsa ntchito batchmatumba ophatikizidwazitha kuthandiza mbewu za rabara kuti zigwirizane bwino, kukhala ndi malo abwino ogwirira ntchito, kupulumutsa zowonjezera zodula, ndikuwonjezera magwiridwe antchito.Matumba a malo osungunuka osiyanasiyana, makulidwe, makulidwe, ndi mitundu alipo kuti akwaniritse zomwe makasitomala amafuna.

| Miyezo Yaumisiri | |

| Malo osungunuka alipo | 72, 85, 100 deg. C |

| Thupi katundu | |

| Kulimba kwamakokedwe | ≥12MPa |

| Elongation panthawi yopuma | ≥300% |

| Maonekedwe | |

| Palibe kuwira, dzenje ndi plasticization osauka. Mzere wosindikizira wotentha ndi wosalala komanso wosalala wopanda chisindikizo chofooka. | |