OEM Customized Batch Inclusion Valve Bags For Carbon Black - Low Melt Valve Bags for Zinc Oxide – Zonpak

OEM Customized Batch Inclusion Valve Bags For Carbon Black - Low Melt Valve Bags for Zinc Oxide – Zonpak Detail:

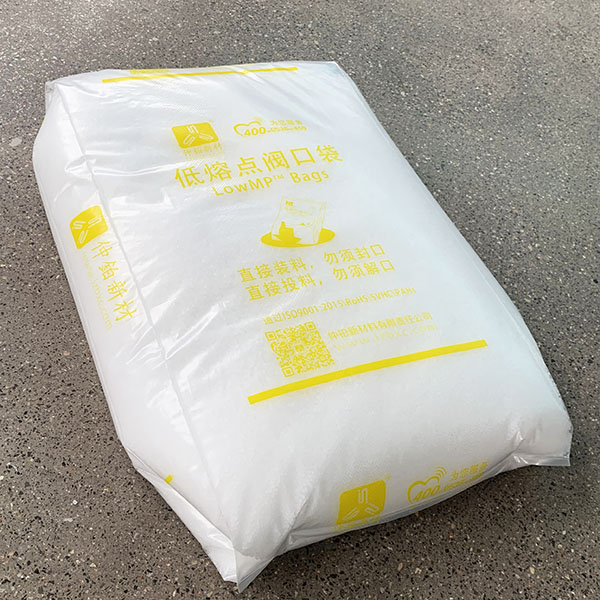

Zinc oxide for rubber industry is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for zinc oxide manufacturers. These bags of zinc oxide can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available as required.

Using the valve bags can avoid the fly loss of the material when packing and there is no need to seal, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

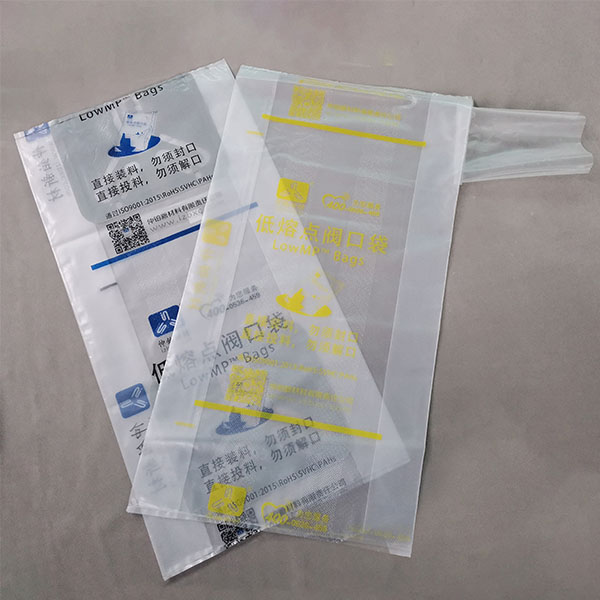

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for OEM Customized Batch Inclusion Valve Bags For Carbon Black - Low Melt Valve Bags for Zinc Oxide – Zonpak, The product will supply to all over the world, such as: Moldova , Panama , Iran , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.