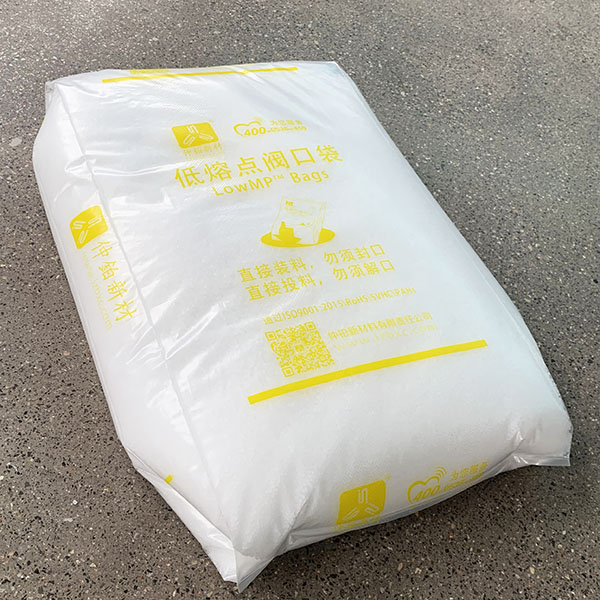

2019 Good Quality Eva Batch Inclusion Bags - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak

2019 Good Quality Eva Batch Inclusion Bags - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak Detail:

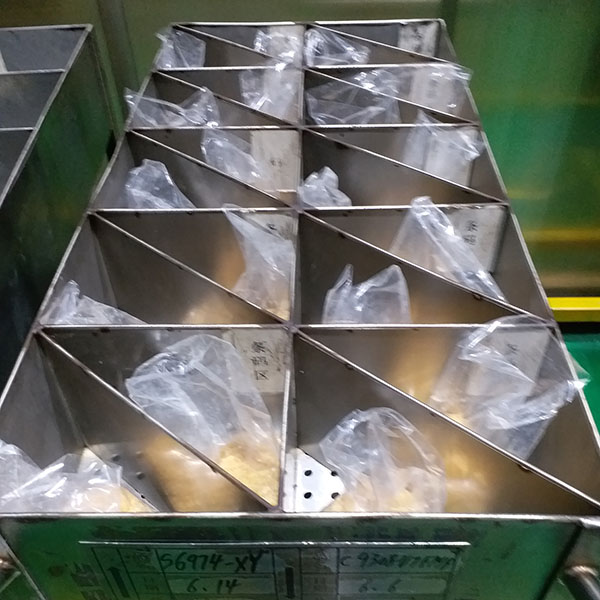

Mixing process is an important part in the manufacture of rubber conveyor belt. ZonpakTM low melt bags are designed for packing the additives or rubber chemicals used in the compounding process. Due to its low melting point and good compatibility with rubber, the batch inclusion bags together with the ingredients packed can be direct put into an internal mixer or mill. The bags can easily melt and disperse into the rubber as an active ingredient. Using the low melt batch inclusion bags can help provide a cleaner work environment, ensure more accurate adding of additives and chemicals, save time and production cost.

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa

TD ≥16MPa |

| Elongation at break | MD ≥400%

TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa

TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for 2019 Good Quality Eva Batch Inclusion Bags - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak, The product will supply to all over the world, such as: Barcelona , Qatar , Adelaide , We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.