2019 Good Quality Low Melting Point Ffs Film - EVA Packaging Film for Rubber Additives – Zonpak

2019 Good Quality Low Melting Point Ffs Film - EVA Packaging Film for Rubber Additives – Zonpak Detail:

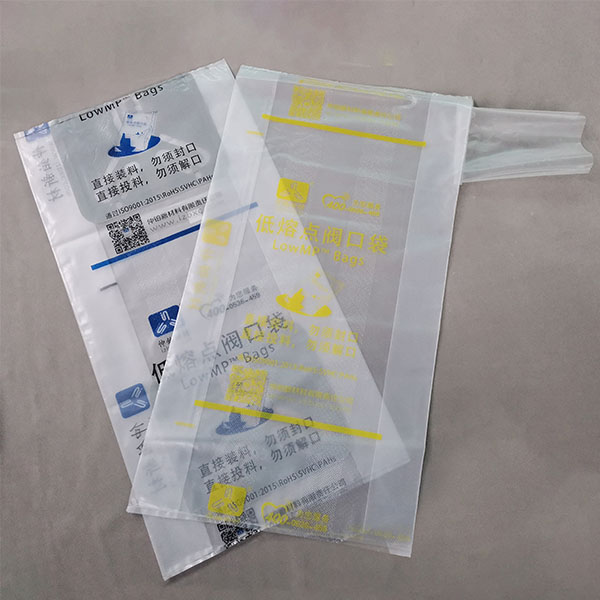

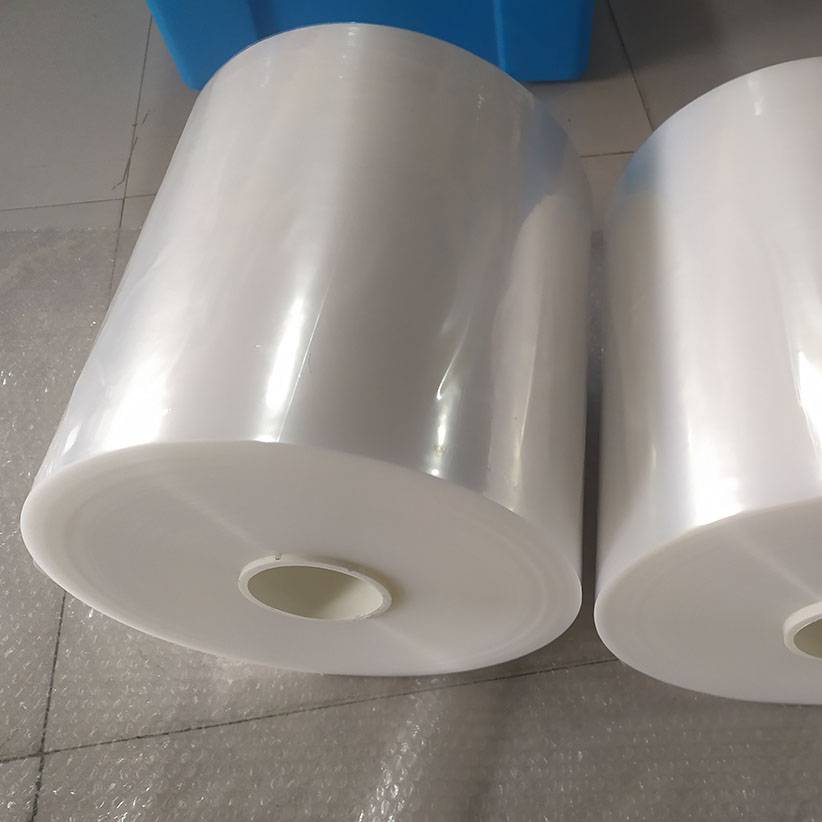

ZonpakTM EVA packaging film is specially designed for making little bags of rubber additives (e.g. 100g-5000g) with a form-fill-seal (FFS) bagging machine. Various rubber additives or chemicals (e.g. peptizer, anti-aging agent, curing agent, cure accelerator, rubber process oil) are commonly used in the rubber mixing process, and only little amounts of these materials are needed for each batch. So these little packages can help the material users increase work efficiency and avoid material waste. The film is made of EVA resin (copolymer of ethylene and vinyl acetate) which has a specific lower melting point and good compatibility with rubber or resin materials. So the bags together with the materials contained can be direct put into a mixer. The bags will melt and disperse into the rubber compound as a minor effective ingredient.

Films with different melting points (65-110 degree Celsius) and thickness are available for different using conditions.

|

Technical Datas |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for 2019 Good Quality Low Melting Point Ffs Film - EVA Packaging Film for Rubber Additives – Zonpak, The product will supply to all over the world, such as: Tunisia , Malta , Naples , Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.