Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Hose Industry – Zonpak

Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Hose Industry – Zonpak Detail:

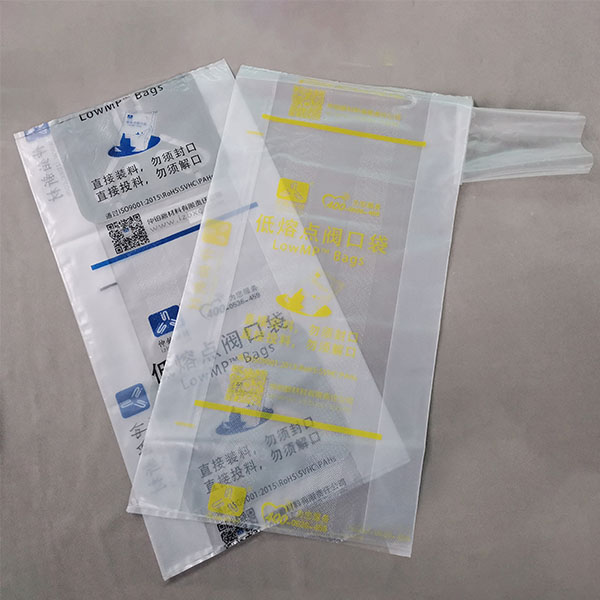

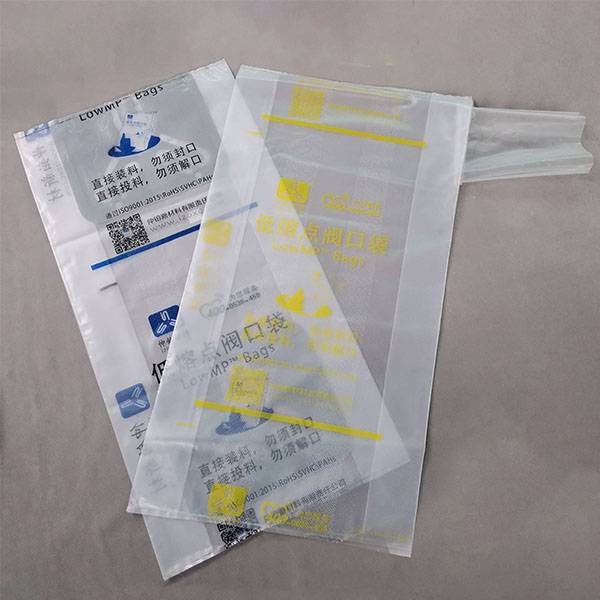

Rubber mixing plays an important role in the production of rubber hose or tube. ZonpakTM low melt EVA batch inclusion bags are designed for packaging the rubber chemicals used in the rubber compounding or mixing process. The main properties of the bags are low melting point and good compatibility with rubber, so the bags together with the additives and chemicals inside can be direct put into an internal mixer or mill. The bags can easily melt and disperse into the rubber as minor effective ingredient. Using the batch inclusion bags can help ensure accurate adding of additives, provide a cleaner work environment, save time and production cost.

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for Best Price for Batch Inclusion Low Melt Bags - Low Melt Bags for Rubber Hose Industry – Zonpak, The product will supply to all over the world, such as: Madagascar , San Diego , Kuwait , For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!