Best Price for Packaging Bag With Valve - Low Melting Point Valve Bags – Zonpak

Best Price for Packaging Bag With Valve - Low Melting Point Valve Bags – Zonpak Detail:

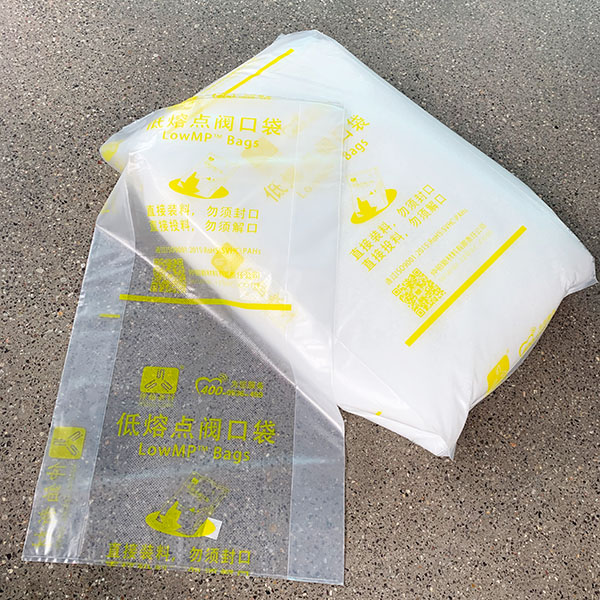

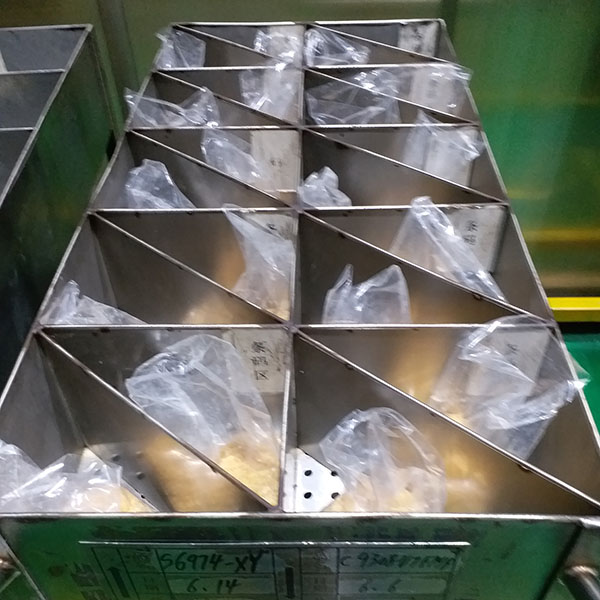

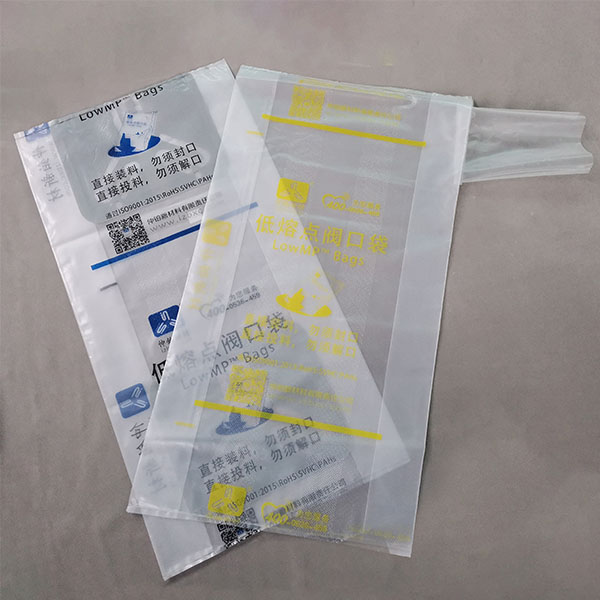

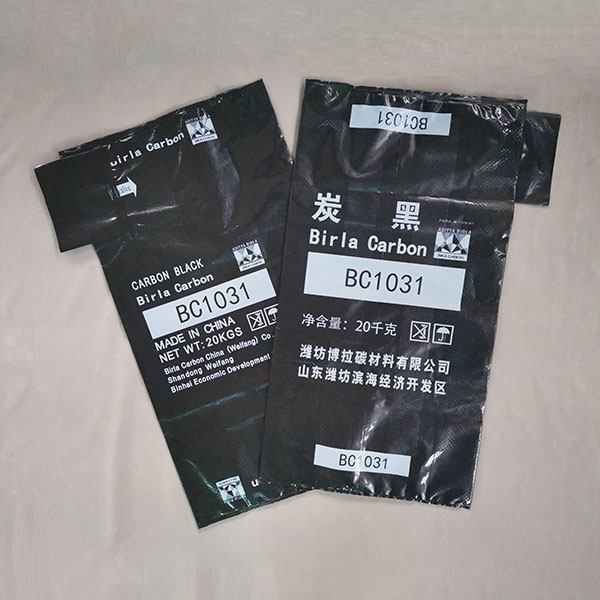

ZonpakTM low melting point valve bags are specially designed for the industrial packaging of rubber chemicals and resin pellets (e.g. carbon black, zinc oxide, silica, calcium carbonate, CPE). Using the low melting bags with an automatic filling machine, material suppliers can make 5kg-25kg packages which can be direct put into an internal mixer by the material users. The bags will melt and fully disperse into the rubber compounds as a minor ingredient.

Benefits of using the low melting point valve bags:

- No fly loss of materials when packing.

- Improve the material packing efficiency.

- Facilitate the stacking and palletizing.

- Help material users reach accurate dosing of materials.

- Provide material users with cleaner work environment.

- Eliminate the disposal of packaging waste

If you are a manufacturer or supplier of rubber additives or resin materials and plan to improve your packaging bags, please have a look at our Low Melt Valve Bags and tell us your specific application and requirements, our experts will help you to choose or design the right bags.Help material users cut down the cleaning cost.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for Best Price for Packaging Bag With Valve - Low Melting Point Valve Bags – Zonpak, The product will supply to all over the world, such as: Argentina , Brasilia , Iran , We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.