Best quality Low Melt Pouch - Low Melt Bags for Tire Industry – Zonpak

Best quality Low Melt Pouch - Low Melt Bags for Tire Industry – Zonpak Detail:

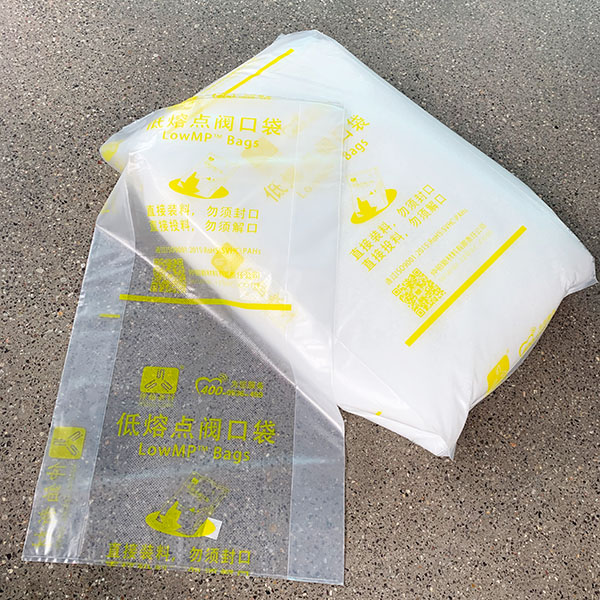

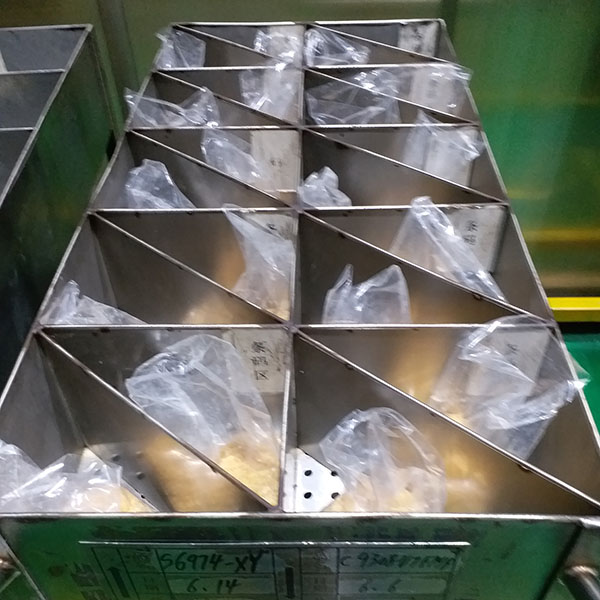

ZonpakTM low melt bags are also called rubber compounding bags or rubber ingredient bags in the tire industry. The bags are specially designed for packing rubber additives and chemicals used in the compounding or mixing process.

Bags with different melting points are suitable for different mixing conditions. Bags with melting point 85 deg. C are the most often used, while bags with melting point 72 deg. C are used for adding of accelerators. Improving work environment, ensuring accurate adding of additives and raising production efficiency are the main benefits of using low melt bags.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for Best quality Low Melt Pouch - Low Melt Bags for Tire Industry – Zonpak, The product will supply to all over the world, such as: Palestine , Turkey , Brunei , Our tenet is "integrity first, quality best". Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!