Chinese Professional Low Melt VFFS Film - EVA Film on Roll for FFS Packaging – Zonpak

Chinese Professional Low Melt VFFS Film - EVA Film on Roll for FFS Packaging – Zonpak Detail:

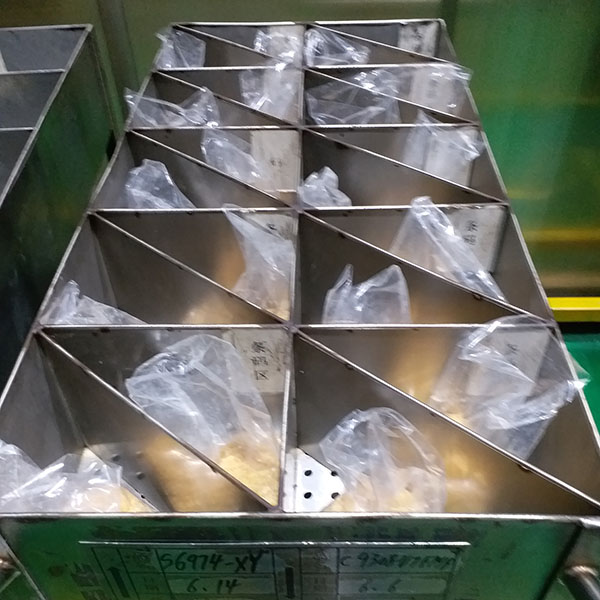

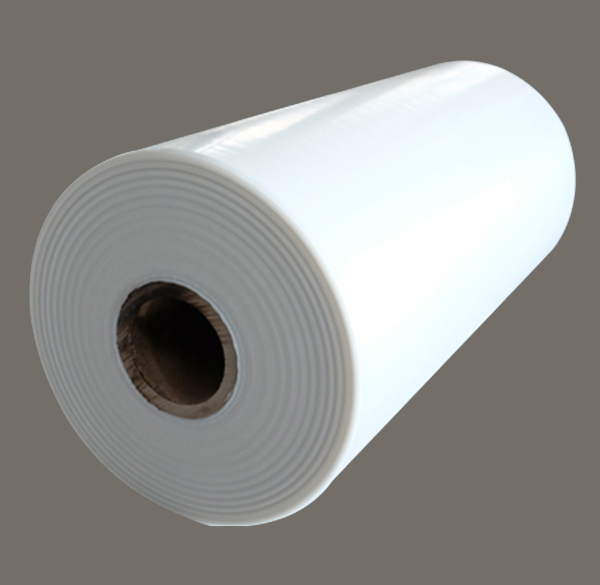

ZonpakTM EVA film roll is specially designed for automatic form-fill-seal (FFS) packaging of rubber chemicals. Manufacturers of rubber chemicals can use the film and FFS machine to make 100g-5000g uniform packages for rubber compounding or mixing plants. These little packages can be direct put into a mixer during the mixing process. The bag made of the film can easily melt and fully disperse into the rubber as a minor effective ingredient. It largely facilitates the work of material users and helps raise production efficiency while eliminate packaging disposal and material waste.

Films with different melting points are available for different application. Thickness and width of the film are to be made as customers’ requirement. If you don’t have specific requirement, just tell us your detailed intending application and the packaging machine type, our experts will help you to choose the right product.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Chinese Professional Low Melt VFFS Film - EVA Film on Roll for FFS Packaging – Zonpak, The product will supply to all over the world, such as: Peru , Seattle , Casablanca , Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.