Chinese wholesale EVA Melting Bags - Low Melt Bags – Zonpak

Chinese wholesale EVA Melting Bags - Low Melt Bags – Zonpak Detail:

It is common that dust of raw materials flies everywhere in the workshop of rubber and tyre plants, which causes environment pullution and can be harmful to the workers’ health. To solve this problem, low melt batch inclusion bags are developed after lots of material analyses and experiments. The bags have particular low melting points and are specially designed for the compounding and mixing of rubber and plastic materials in industrial process. Workers can use these bags to pre-weigh and temporarily store the ingredients and additives. In the mixing process, the bags together with the materials contained can be direct put into a mixing machine as the quality of the final product will not be compromised. The using of the low melting batch inclusion bags largely improves the production environment, minimizes the worker exposure to hazardous materials, makes the weighing of the materials easier and increases the production efficiency.

Properties:

- The bags have low melting points: 70-110℃. Different melting points are available according to customers’ requirement. The bags can be direct put into a mill or mixer due to its good meltability and dispersity in rubber and plastic.

- The bags have good tensile strength, impact strength, puncture resistance, flexibility, and rubber-like elasticity.

- The bags have excellent chemical stability, no toxicity, good environmental stress cracking resistance, weather resistance and compatibility with the rubber materials. Decomposition products of the bag can be compatibly blended with natural rubber, styrene butadiene rubber (SBR), butadiene rubber (BR), solution polymerized butadiene styrene rubber (SSBR), polyisoprene rubber and high styrene resin, without affecting the physical and chemical properties of the rubber, and it can be used as an active ingredient of the rubber formula, reducing the production cost and avoiding packing waste.

Applications:

These bags are mainly used for packaging various chemical materials and reagents (e.g. white carbon black, carbon black, anti-aging agent, accelerator, sulphur and aromatic hydrocarbon oil) in the rubber industry (tire, hose, tape, shoes), plastic processing industry (PVC, plastic pipe and extrude ) and rubber and plastic additives industry.

|

Technical Standards |

|

| Melting point | 70-110℃ |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

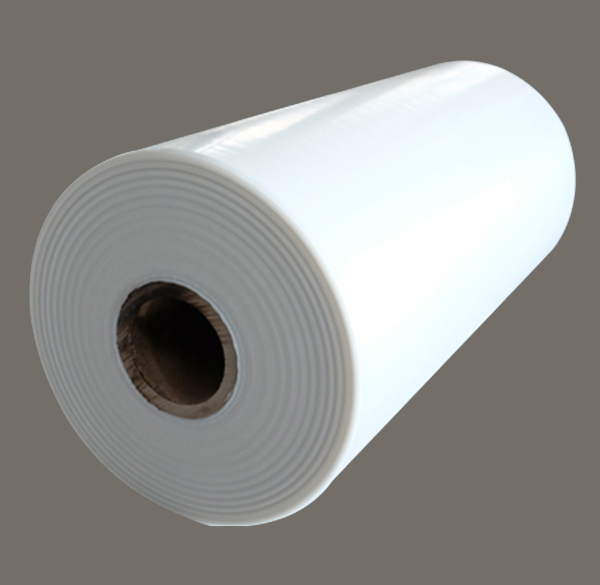

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for Chinese wholesale EVA Melting Bags - Low Melt Bags – Zonpak, The product will supply to all over the world, such as: Pretoria , Angola , Panama , We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!