Factory Supply - Low Melt Valve Bags for Carbon Black – Zonpak

Factory Supply - Low Melt Valve Bags for Carbon Black – Zonpak Detail:

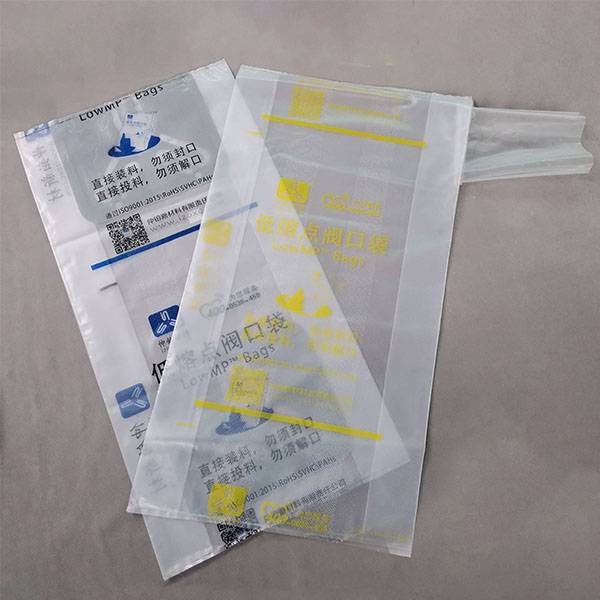

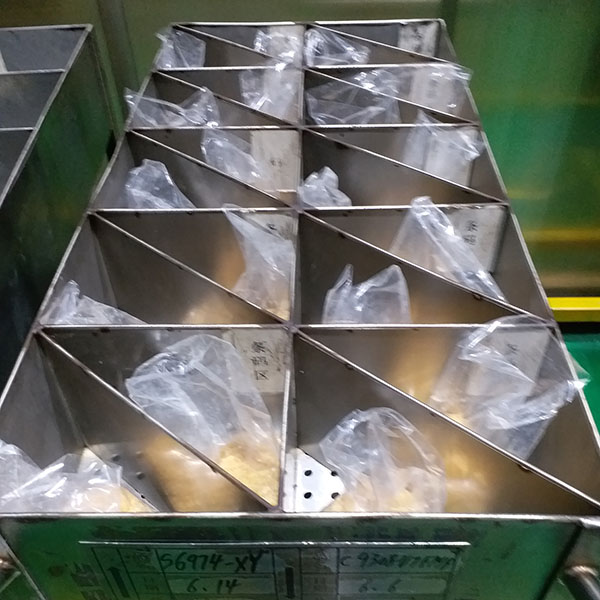

These bags are specially designed for the packaging of rubber additive Carbon Black. With low melt valve bags and an automatic filling machine, carbon black manufacturers can make standard packages of 5kg, 10kg, and 20kg. Using the valve bags can eliminate fly loss of the material when packing. As there is no need for sealing, it largely improves the packaging efficiency.

The valve bags are made from EVA (copolymer of ethylene and vinyl acetate) which has a lower melting point than PE and is highly compatible with rubber, so the bags of carbon black can be direct put into an internal mixer, and the bags can fully disperse in the rubber as a minor effective ingredient. Bags with different melting points are available for different mixing conditions. With standard packages and no need for unpacking before using the material, these bags also facilitate the work of the material users.

OPTIONS:

- Gusset or block bottom form, embossing, venting, color, printing

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Factory Supply - Low Melt Valve Bags for Carbon Black – Zonpak, The product will supply to all over the world, such as: Qatar , Chile , Riyadh , We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.