Factory wholesale EVA Plastic Bag - Rubber Compounding Bags – Zonpak

Factory wholesale EVA Plastic Bag - Rubber Compounding Bags – Zonpak Detail:

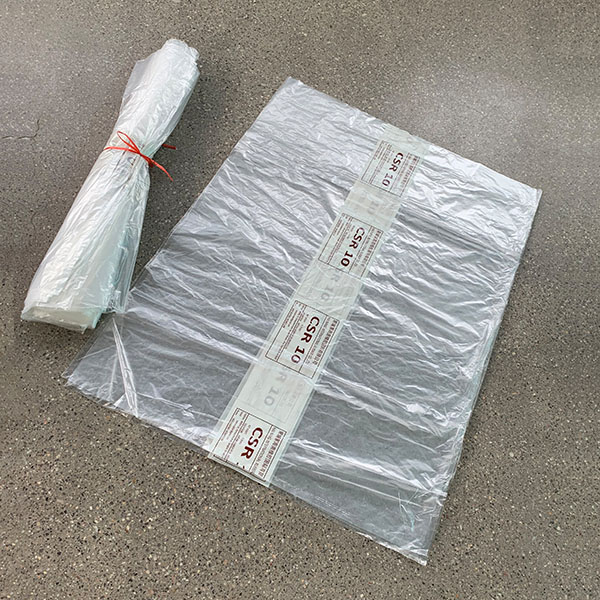

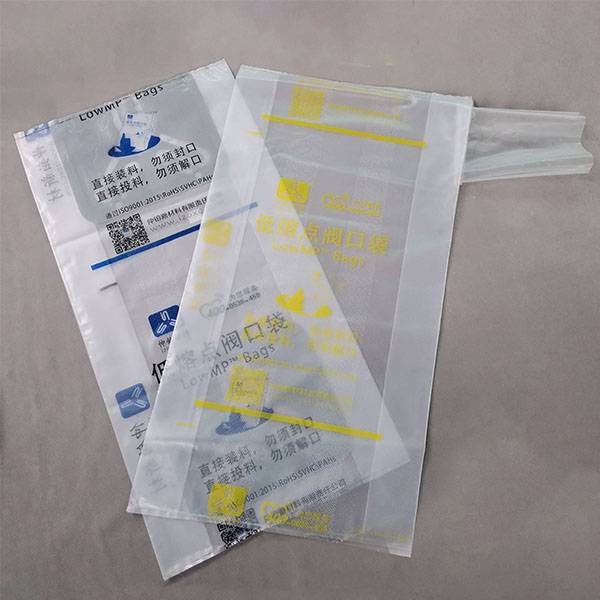

Rubber compounding refers to the addition of certain chemicals to raw rubber in order to obtain the desired properties. ZonpakTM rubber compounding bags are specially designed bags for packing rubber ingredients and chemicals used in the rubber compounding process. The materials e.g. black carbon, anti-aging agent, accelerator, curing agent and aromatic hydrocarbon oil can be preweighed and temporarily stored in the EVA bags. As the material of the bags has good compatibility with natural and synthetic rubber, these bags together with the materials packed can be direct put into a mixer, and the bags will melt and fully disperse into the rubber as a minor effective ingredient.

These bags largely help rubber compounding work by providing exact adding of chemicals, cleaner work environment and higher practice efficiency.

Bags with different melting point (from 65 to 110 degree Celsius) are available for different rubber mixing conditions. Size and color can be customized according to the customer’s specific application requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Factory wholesale EVA Plastic Bag - Rubber Compounding Bags – Zonpak, The product will supply to all over the world, such as: Frankfurt , Italy , Indonesia , We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.