Factory wholesale Low Melt Sacks - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak

Factory wholesale Low Melt Sacks - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak Detail:

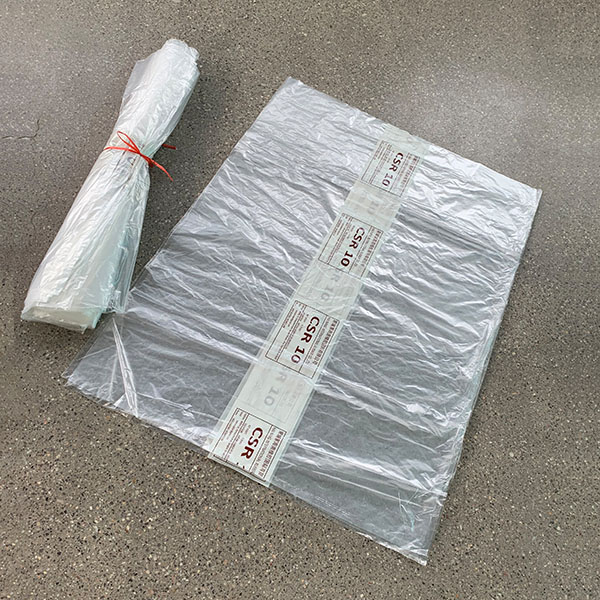

Mixing process is an important part in the manufacture of rubber conveyor belt. ZonpakTM low melt bags are designed for packing the additives or rubber chemicals used in the compounding process. Due to its low melting point and good compatibility with rubber, the batch inclusion bags together with the ingredients packed can be direct put into an internal mixer or mill. The bags can easily melt and disperse into the rubber as an active ingredient. Using the low melt batch inclusion bags can help provide a cleaner work environment, ensure more accurate adding of additives and chemicals, save time and production cost.

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa

TD ≥16MPa |

| Elongation at break | MD ≥400%

TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa

TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Factory wholesale Low Melt Sacks - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak, The product will supply to all over the world, such as: Luxembourg , Karachi , Maldives , With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.