Fast delivery Low Melt EVA Bags For Silica - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak

Fast delivery Low Melt EVA Bags For Silica - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak Detail:

Mixing process is an important part in the manufacture of rubber conveyor belt. ZonpakTM low melt bags are designed for packing the additives or rubber chemicals used in the compounding process. Due to its low melting point and good compatibility with rubber, the batch inclusion bags together with the ingredients packed can be direct put into an internal mixer or mill. The bags can easily melt and disperse into the rubber as an active ingredient. Using the low melt batch inclusion bags can help provide a cleaner work environment, ensure more accurate adding of additives and chemicals, save time and production cost.

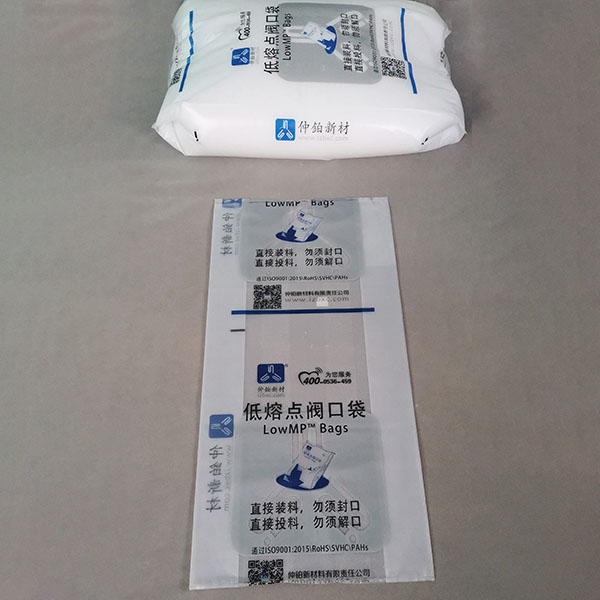

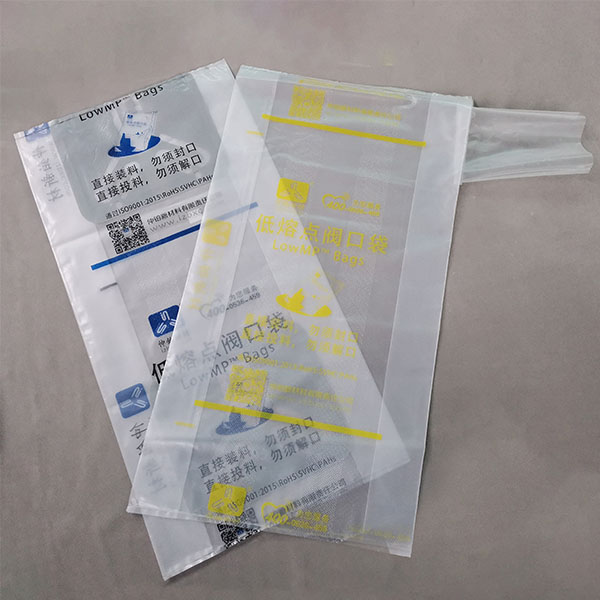

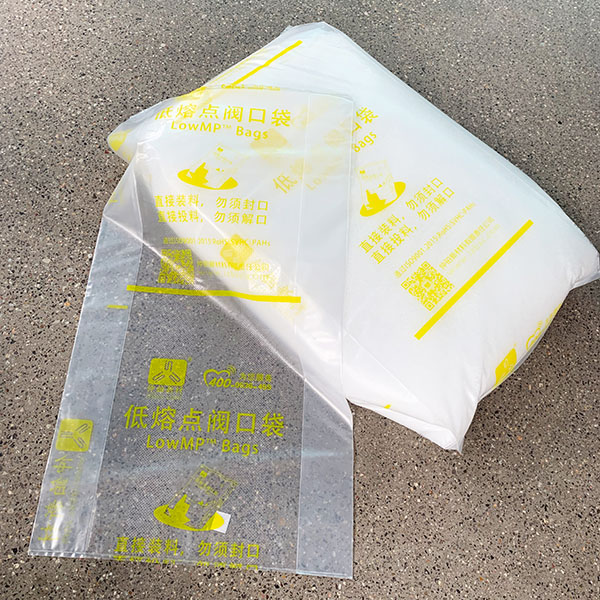

Bag size and color can be customized at request.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa

TD ≥16MPa |

| Elongation at break | MD ≥400%

TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa

TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

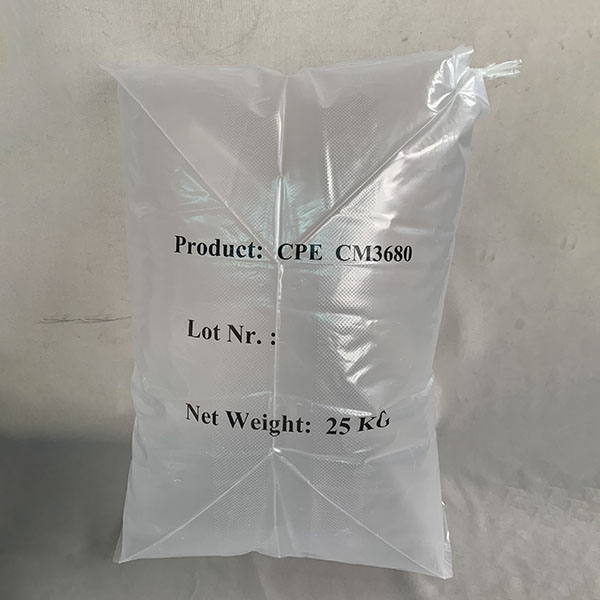

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Fast delivery Low Melt EVA Bags For Silica - Low Melt Bags for Rubber Conveyor Belt Industry – Zonpak, The product will supply to all over the world, such as: Cyprus , New York , Sudan , We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.