High Quality for EVA Film For Bag Making - Low Melt EVA Packaging Film – Zonpak

High Quality for EVA Film For Bag Making - Low Melt EVA Packaging Film – Zonpak Detail:

ZonpakTM Low melt EVA packaging film is specially designed for the FFS (Form-Fill-Seal) automatic packaging of rubber and plastic processing additives. And it was developed after analyzing of the raw materials used in the tire and rubber factories and lots of experiments on automatic packing machines. The FFS packaging machine can accurately weigh the materials, then pack with the film and seal automatically. Due to the film’s properties of low melting point and good compatibility with rubber and other polymers, the bag together with the materials contained can be direct put into a mixing machine without affecting the product quality. Using this low melt packaging film can largely increase the production automation and efficiency, improve the working environment, and reduce the production cost. Rubber and plastic additive factories can use this film to make uniform little packages for the users’ convenience.

PROPERTIES:

l Different melting points are available according to customers’ requirement. The film has good meltability and dispersity in rubber and plastic. The packages of additives can be direct put into the mill or mixer. Strong physical properties of the film make it suitable for most of the automatic packaging machine.

l The film material is non-toxic, has good chemical stability, environmental stress cracking resistance, weather resistance and compatibility with rubber and plastic materials. The film can be compatibly blended with natural rubber, styrene butadiene rubber (SBR), butadiene rubber (BR), Solution polymerized butadiene styrene rubber (SSBR), polyisoprene rubber, high styrene resin and many other resins, without affecting the physical and chemical property of the rubber, and it can be used as an active ingredient of the rubber formula, reducing the production cost and packaging waste.

APPLICATIONS:

This product is mainly used for little and middle size packages (less than 10kg) of various chemical materials and reagents (e.g. peptizer, anti-aging agent, accelerator, curing agent and aromatic hydrocarbon oil) in the rubber industry (tire, hose, belt, shoes), plastic processing industry (PVC, plastic pipe and extrude) and rubber and plastic additives industry.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

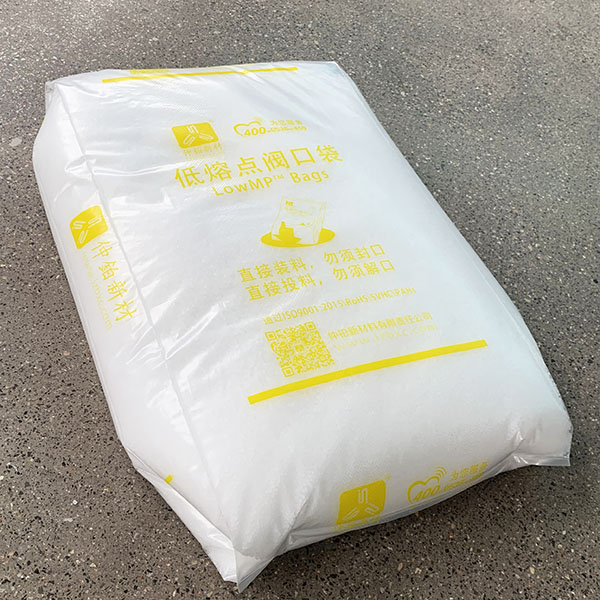

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for High Quality for EVA Film For Bag Making - Low Melt EVA Packaging Film – Zonpak, The product will supply to all over the world, such as: Switzerland , Denver , Bolivia , Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.