High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Calcium Carbonate – Zonpak

High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Calcium Carbonate – Zonpak Detail:

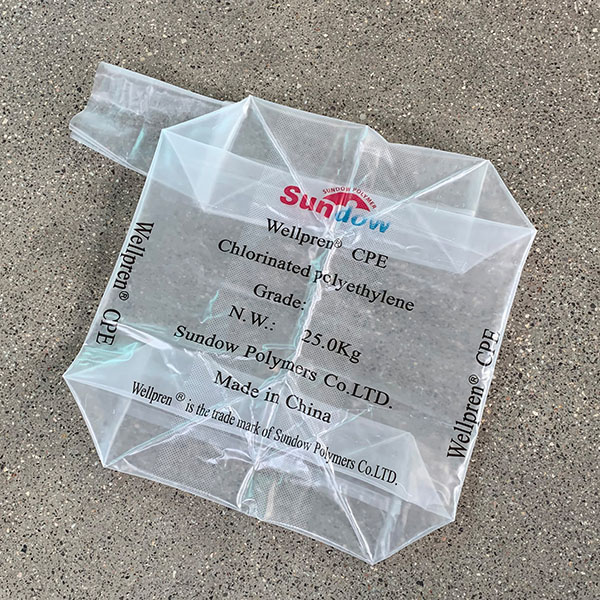

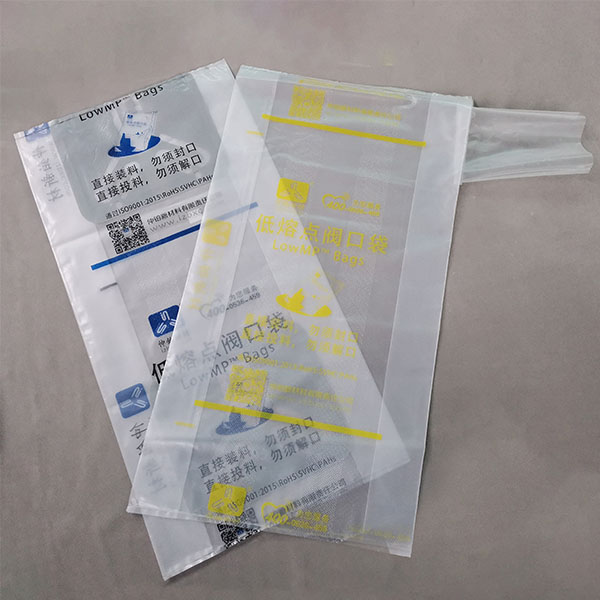

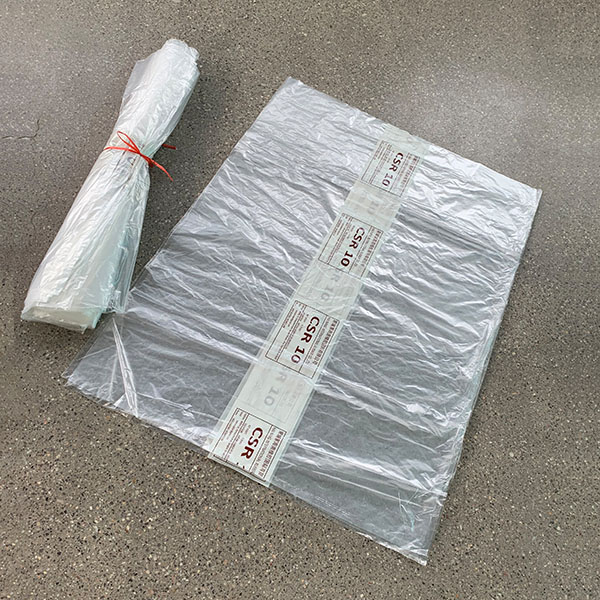

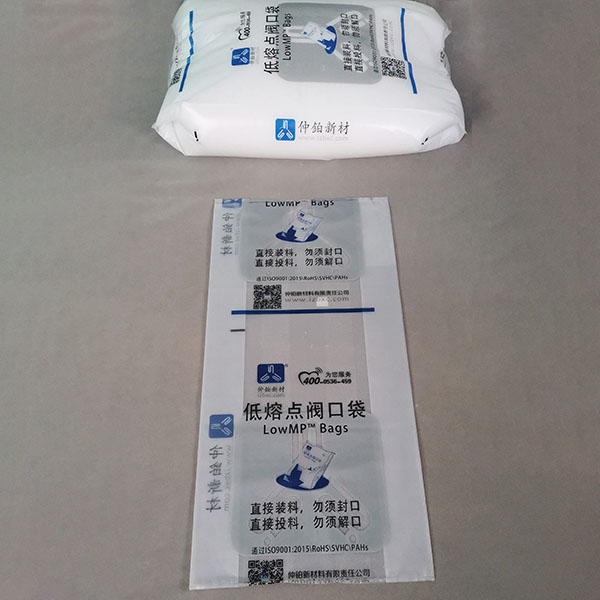

Calcium carbonate for rubber industry is usually packed in kraft paper bags which are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for calcium carbonate manufacturers. These bags together with the materials contained can be direct put into an internal mixer because they can easily melt and fully disperse in the rubber compounds as an effective ingredient. Different melting points (65-110 degree Celsius) are available for different using conditions.

BENEFITS:

- No fly loss of materials

- Improve packing efficiency

- Easy piling up and handling of materials

- Assure accurate adding of materials

- Cleaner work environment

- No need for disposal of packaging waste

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Calcium Carbonate – Zonpak, The product will supply to all over the world, such as: Swedish , Bahrain , Finland , We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.