High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Rubber Additives – Zonpak

High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Rubber Additives – Zonpak Detail:

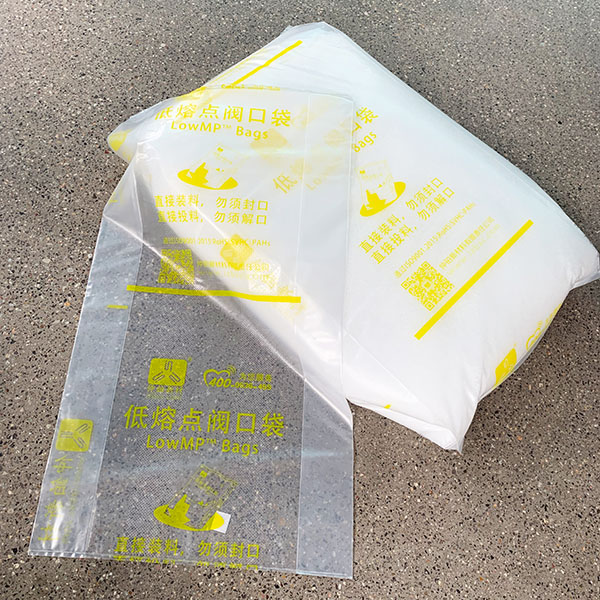

Rubber additives in form of powder or granule include carbon black, white carbon black, zinc oxide, and calcium carbonate are usually packed in kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for rubber additives manufacturers. These bags together with the materials contained can be direct put into an internal mixer because they can easily melt and fully disperse into the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different application conditions.

BENEFITS:

- No fly loss of materials

- Improve packing efficiency

- Easy piling up and handling of materials

- Assure accurate adding of materials

- Cleaner work environment

- No need for disposal of packaging waste

APPLICATIONS:

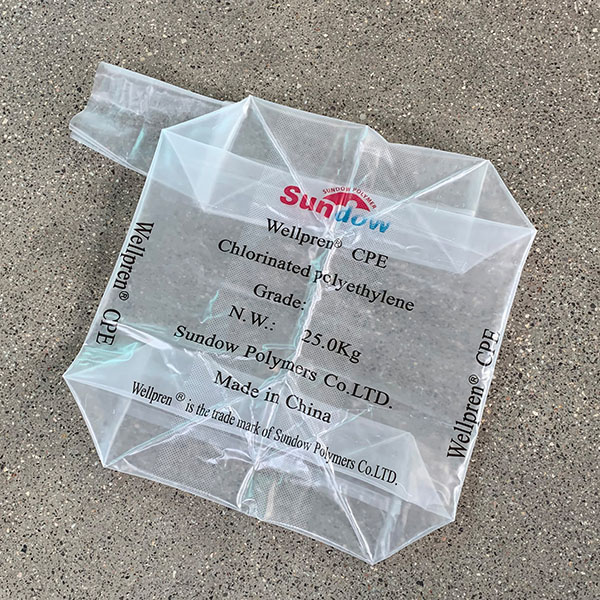

- rubber, CPE, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay, rubber process oil

OPTIONS:

Bag size, color, embossing, venting, printing

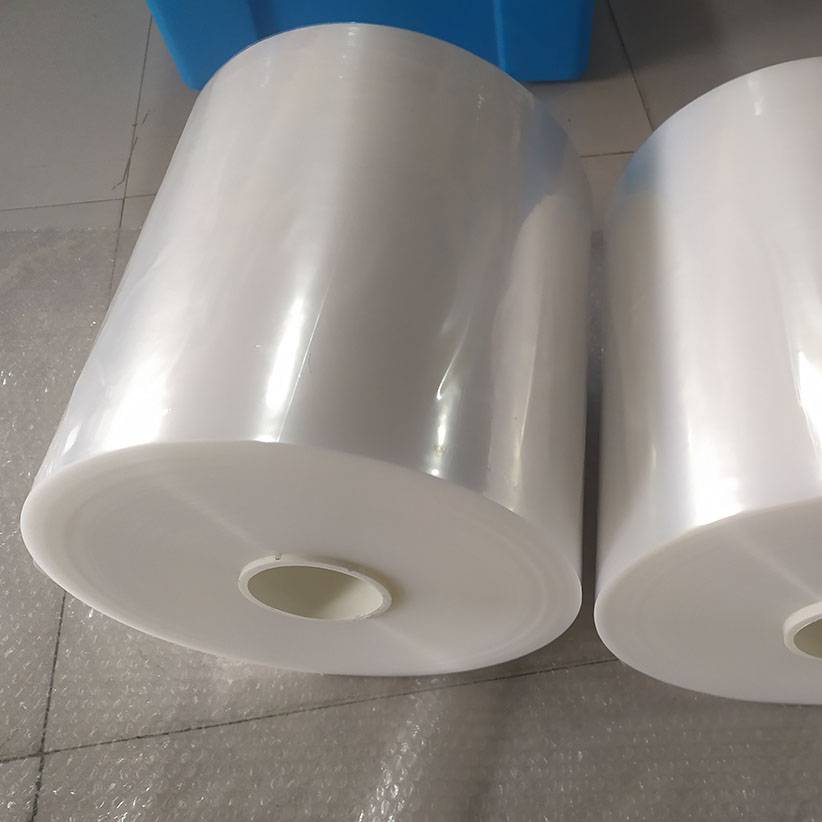

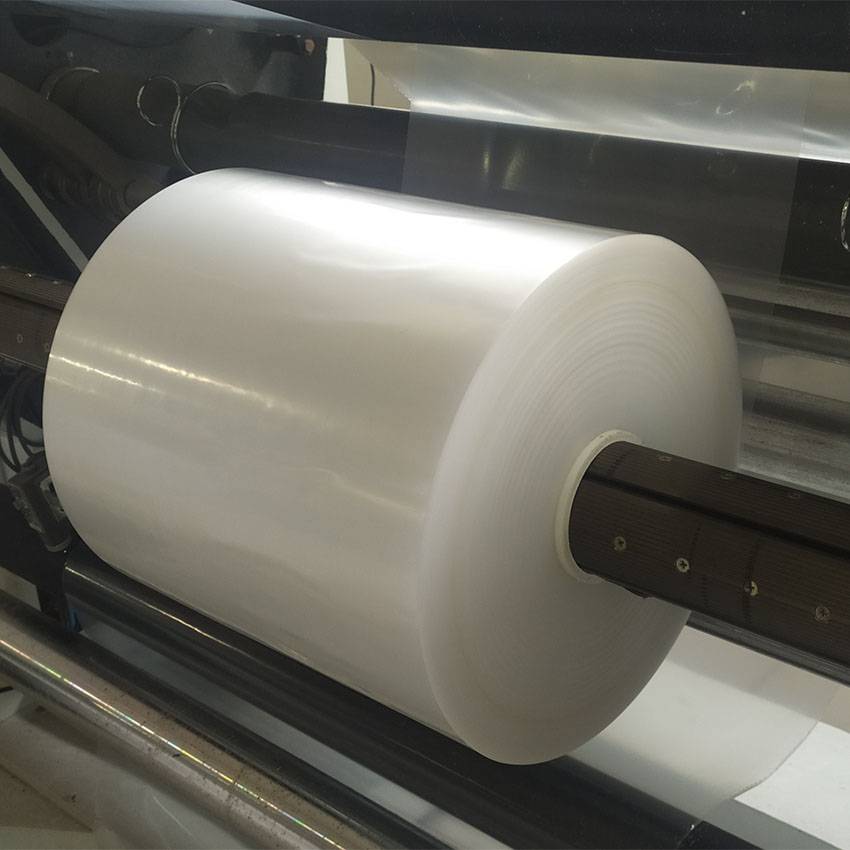

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for High Quality for Low Melt EVA Valve Bags - Low Melt Valve Bags for Rubber Additives – Zonpak, The product will supply to all over the world, such as: Rome , South Africa , Turkmenistan , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.