High Quality Low Melt Bags - Batch Inclusion Bags – Zonpak

High Quality Low Melt Bags - Batch Inclusion Bags – Zonpak Detail:

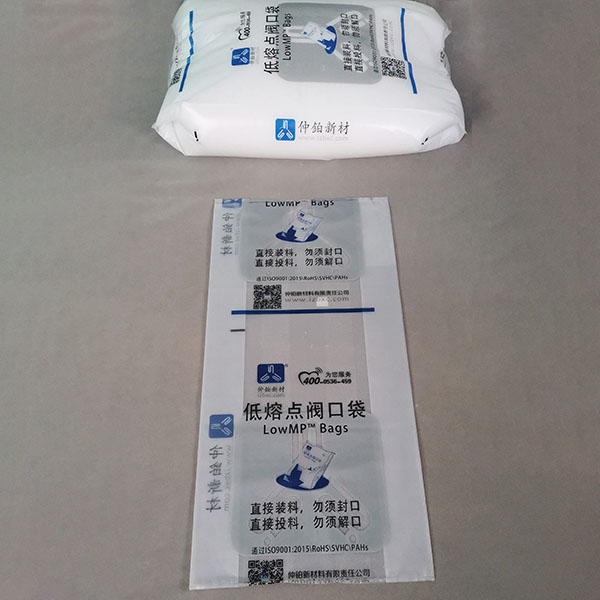

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into an internal mixer. The bags can easily melt and fully disperse into the rubber as a minor ingredient.

Using batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and increase work efficiency. Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 72, 85, 105 deg. C |

| Physical properties | |

| Tensile strength | MD ≥12MPa, TD ≥12MPa |

| Elongation at break | MD ≥300%, TD ≥300% |

| Appearance | |

| There is no bubble, hole and poor plasticization. Hot sealing line is flat and smooth without weak seal. | |

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for High Quality Low Melt Bags - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Iraq , Canada , Philadelphia , We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.