High Quality Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak

High Quality Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak Detail:

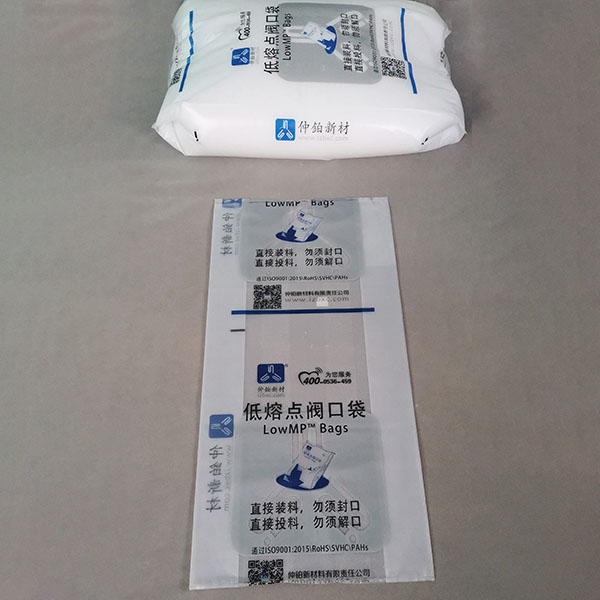

ZonpakTM low melt bags are specially designed for packing rubber ingredients and chemicals used in the rubber compounding process. The materials e.g. black carbon, anti-aging agent, accelerator, curing agent and aromatic hydrocarbon oil can be pre-weighed and temporarily stored in these bags. Due to their good compatibility with natural and synthetic rubber, these bags together with the materials inside can be direct put into an internal mixer, and the bags will melt and fully disperse in the rubber as a minor effective ingredient.

BENEFITS:

- Accurate adding of ingredients and chemicals

- Easy pre-weighing and storing

- Clean mixing area

- No waste of additives and chemicals

- Reduce workers’ exposure to the harmful materials

- Less labor and time needed

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-100 micron

- Bag width: 200-1200 mm

- Bag length: 250-1500mm

Product detail pictures:

Related Product Guide:

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for High Quality Low Melt Bags - Low Melt Bags for Rubber Compounding – Zonpak, The product will supply to all over the world, such as: South Korea , Turin , Turkmenistan , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.