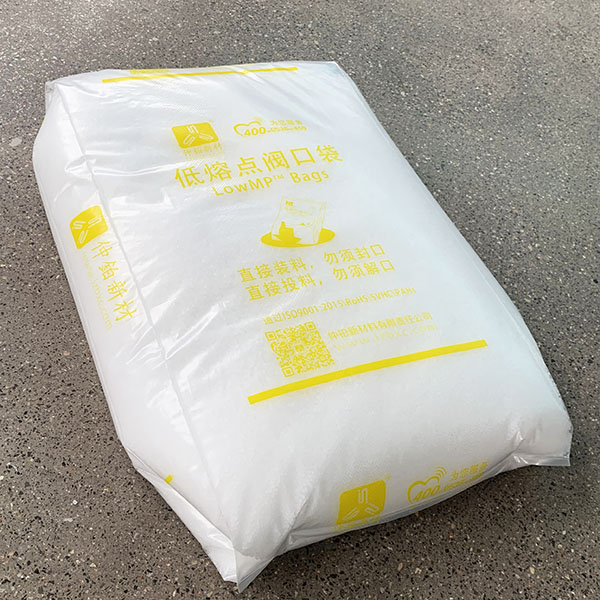

Hot sale Batch Inclusion Bags For Rubber Seals Manufacture - Low Melting Point Plastic Bags – Zonpak

Hot sale Batch Inclusion Bags For Rubber Seals Manufacture - Low Melting Point Plastic Bags – Zonpak Detail:

ZonpakTM low melting point plastic bags are made from EVA (Ethylene Vinyl Acetate), and are mainly used to pack compounding ingredients (e.g. liquid aromatic hydrocarbons and powder additives) in tire and rubber industries. Due to the property of low melting point and good compatibility with rubber, the bags together with the additives contained can be direct put into a mixer or mill and fully disperse into the rubber as a minor effective ingredient, so it can provide accurate dosing of additives and cleaner work environment. Using the bags can help rubber plants get uniform rubber compounds while save additives and time.

Melting point, size and color can be customized according to the customer’s specific application requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Hot sale Batch Inclusion Bags For Rubber Seals Manufacture - Low Melting Point Plastic Bags – Zonpak, The product will supply to all over the world, such as: Czech Republic , Switzerland , Dominica , Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.