Hot Sale for Valve Bags For Chemical - Low Melt EVA Valve Bags – Zonpak

Hot Sale for Valve Bags For Chemical - Low Melt EVA Valve Bags – Zonpak Detail:

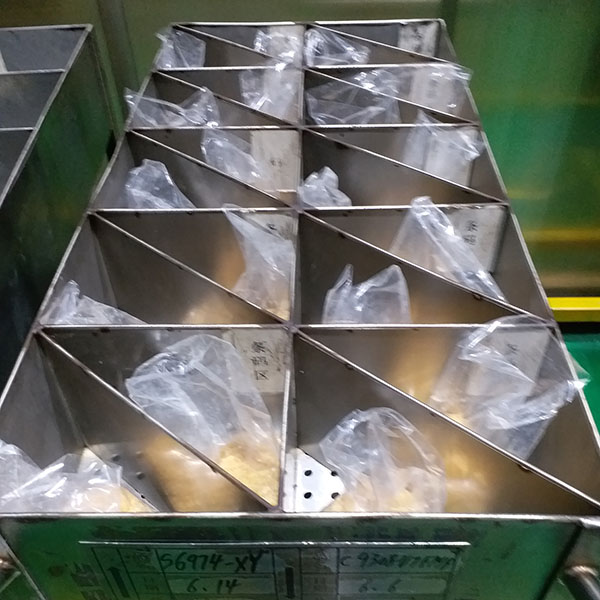

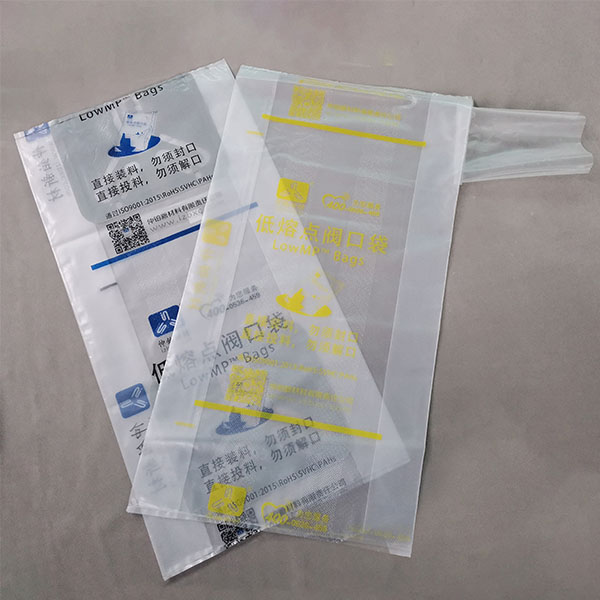

ZonpakTM Low melt EVA valve bags are specially designed packaging bags for rubber additives and resin pellets. These bags are to be used with an automatic filling machine. Pack the materials with low melt EVA valve bags, there is no need for sealing after filled and no need for unsealing before putting the bags of material into a banbury mixer. So these EVA valve bags are ideal substitute for traditional kraft and PE heavy duty bags.

High speed and quantitative filling can be achieved by simply placing the valve port on the top or at bottom of the bag to the spout of a filling machine. Different types of valve are available to match different filling machines and materials. The valve bags are made of new materials, featured with low melting point, good compatibility with rubber, solid and high impact resistance. After filled the bag turns into a flat cuboid, can be piled up neatly. It is suitable for the packaging of various particle, powder, and ultra-fine powder materials.

PROPERTIES:

Bags with different melting points are available to meet customers’ particular requirement.

They have good meltability and dispersity in the rubber and plastics.

With high tensile strength, impact strength and resistance to puncture, the bags can suit various filling machines.

The bags have excellent chemical stability, no toxicity, good environmental stress cracking resistance, weather resistance and compatibility with the rubber materials e.g. NR, BR, SBR, NBR.

APPLICATIONS:

These bags are mainly used for packages of 10-25kg of various particle or powder materials (e.g. CPE, carbon black, white carbon black, zinc oxide, calcium carbonate) in the rubber industry (tire, hose, tape, shoes), plastic processing industry (PVC, plastic pipe and extrude ) and rubber chemical industry.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat, there is no wrinkle, no bubble. | |

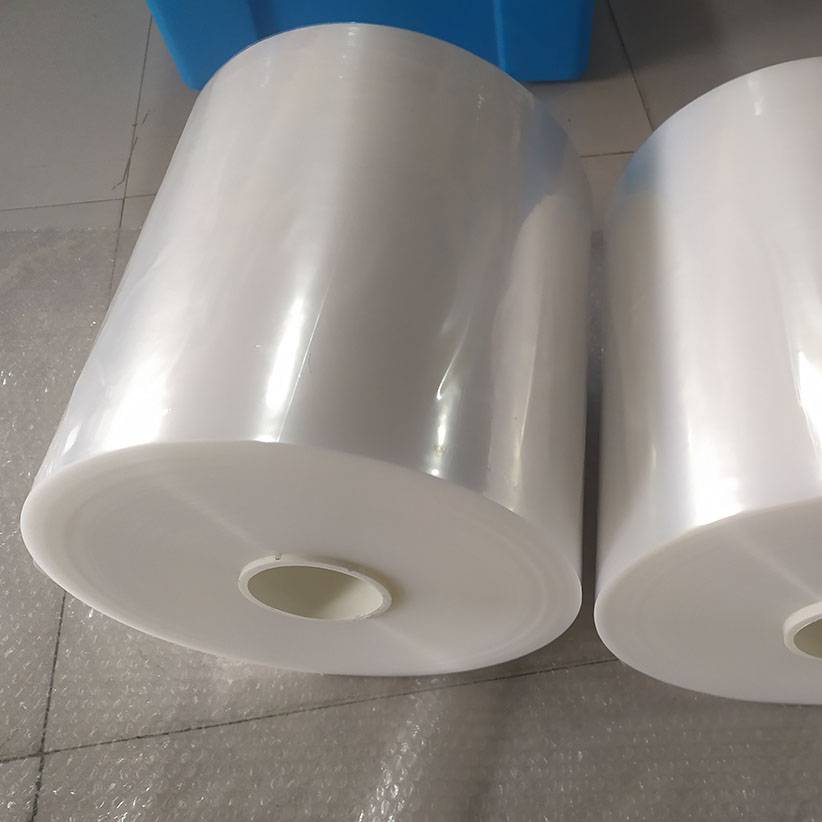

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Hot Sale for Valve Bags For Chemical - Low Melt EVA Valve Bags – Zonpak, The product will supply to all over the world, such as: Algeria , Argentina , Belgium , We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.