Akpa Valve Eva dị ala gbazere

ZonpakTMAkpa valvụ EVA gbazere dị ala bụ akpa nkwakọ ngwaahịa ahaziri maka mgbakwunye rọba na pellet resin. A ga-eji igwe na-ejuputa akpaka akpa ndị a. Gwakọta ihe ndị ahụ na obere akpa valvụ EVA gbazere, ọ dịghị mkpa ka a na-emechi ya mgbe ọ gwụchara ma ọ dịghị mkpa ịmeghe ya tupu ị tinye akpa nke ihe n'ime mixer banbury. Ya mere, akpa valvụ Eva ndị a bụ ezigbo nnọchi maka kraft ọdịnala na akpa ọrụ PE dị arọ.

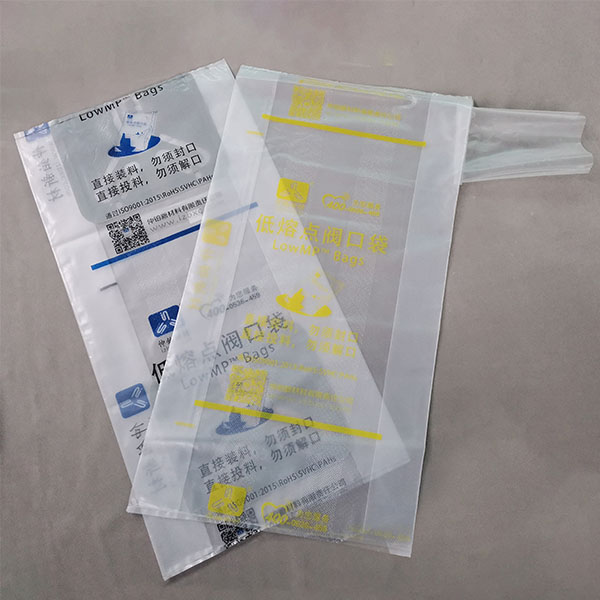

Enwere ike nweta oke ọsọ na ndochi ọnụ site na itinye naanị ọdụ ụgbọ mmiri valvụ n'elu ma ọ bụ na ala nke akpa ahụ na oghere nke igwe na-ejuputa. Ụdị valvụ dị iche iche dị maka igwe na-ejuputa dị iche iche na ihe. A na-eji akpa valvụ mee ihe ọhụrụ, nke a na-egosipụta na ebe mgbaze dị ala, ezigbo ndakọrịta na roba, nguzogide siri ike na nnukwu mmetụta. Mgbe emejuchara akpa ahụ na-atụgharị ghọọ cuboid dị larịị, enwere ike ikpokọta ya nke ọma. Ọ dabara maka nkwakọ ngwaahịa dị iche iche, ntụ ntụ, na ihe ntụ ntụ dị mma.

ALA:

Akpa nwere ebe mgbaze dị iche iche dị iji gboo mkpa ndị ahịa chọrọ.

Ha nwere ezigbo meltability na mgbasa na roba na plastik.

Site na ike ike dị elu, ike mmetụta na nguzogide ntupu, akpa ndị ahụ nwere ike dabara igwe ndochi dị iche iche.

The akpa nwere magburu onwe kemịkalụ nkwụsi ike, ọ dịghị toxicity, ezigbo gburugburu ebe obibi mgbawa mgbawa nguzogide, ihu igwe na-eguzogide na ndakọrịta na ihe roba eg NR, BR, SBR, NBR.

Ngwa:

A na-ejikarị akpa ndị a maka ngwugwu 10-25kg nke ihe dị iche iche ma ọ bụ ihe ntụ ntụ (dịka CPE, carbon black, white carbon black, zinc oxide, calcium carbonate) na ụlọ ọrụ roba ( taya, eriri, teepu, akpụkpọ ụkwụ), nhazi plastik. ụlọ ọrụ (PVC, ọkpọkọ plastik na extrude) na ụlọ ọrụ kemịkalụ roba.

| Ụkpụrụ nka nka | |

| Ebe mgbaze | 65-110 nkeji. C |

| Njirimara anụ ahụ | |

| Ike ọdụdọ | MD ≥16MPaTD ≥16MPa |

| Elongation na ezumike | MD ≥400%TD ≥400% |

| Modul na 100% elongation | MD ≥6MPaTD ≥3MPa |

| Ọdịdị | |

| N'elu ngwaahịa ahụ dị larịị, ọ dịghị afụ, ọ dịghị afụ. | |