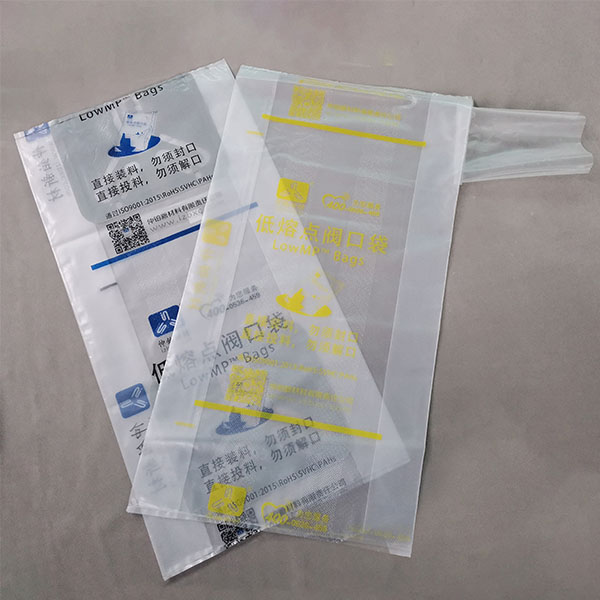

EVA ventilske vrečke z nizko stopnjo taljenja

ZonpakTMVentilne vrečke EVA z nizko stopnjo taljenja so posebej oblikovane embalažne vrečke za gumijaste dodatke in smolne pelete. Te vrečke je treba uporabljati z avtomatskim polnilnim strojem. Zapakirajte materiale z vrečkami z ventilom EVA z nizko stopnjo taljenja, po polnjenju ni potrebe po tesnjenju in ni potrebe po odpiranju, preden vrečke materiala vstavite v mešalnik Banbury. Zato so te ventilske vrečke EVA idealen nadomestek za tradicionalne kraft in PE vrečke za težke obremenitve.

Visoko hitrost in kvantitativno polnjenje je mogoče doseči s preprosto namestitvijo odprtine ventila na vrh ali dno vrečke na dulec polnilnega stroja. Na voljo so različne vrste ventilov, ki ustrezajo različnim polnilnim strojem in materialom. Ventilske vrečke so izdelane iz novih materialov, odlikuje jih nizko tališče, dobra združljivost z gumo, trdnost in visoka odpornost na udarce. Po polnjenju se vrečka spremeni v ploščat kvader, ki ga je mogoče lepo zložiti. Primeren je za pakiranje različnih delcev, prahu in ultra finih praškastih materialov.

LASTNOSTI:

Vreče z različnimi tališči so na voljo za izpolnitev posebnih zahtev strank.

Imajo dobro talilnost in disperzijo v gumi in plastiki.

Z visoko natezno trdnostjo, udarno trdnostjo in odpornostjo na predrtje lahko vrečke ustrezajo različnim polnilnim strojem.

Vrečke imajo odlično kemično stabilnost, niso strupene, imajo dobro odpornost proti pokanju zaradi obremenitve v okolju, odpornost na vremenske vplive in združljivost z gumijastimi materiali, npr. NR, BR, SBR, NBR.

PRIJAVE:

Te vreče se večinoma uporabljajo za pakete 10-25 kg različnih materialov v obliki delcev ali prahu (npr. CPE, saje, bele saje, cinkov oksid, kalcijev karbonat) v gumarski industriji (pnevmatike, cevi, trakovi, čevlji), predelavi plastike industrija (PVC, plastične cevi in ekstrudiranje) in gumarska kemična industrija.

| Tehnični standardi | |

| Tališče | 65-110 stopinj. C |

| Fizikalne lastnosti | |

| Natezna trdnost | MD ≥16MPaTD ≥16MPa |

| Raztezek ob prelomu | MD ≥400 %TD ≥400 % |

| Modul pri 100 % raztezku | MD ≥6MPaTD ≥3MPa |

| Videz | |

| Površina izdelka je ravna, brez gub ali mehurčkov. | |