Manufactur standard Batch Inclusion Bags For Silica - Low Melt Valve Bags for Calcium Carbonate – Zonpak

Manufactur standard Batch Inclusion Bags For Silica - Low Melt Valve Bags for Calcium Carbonate – Zonpak Detail:

Calcium carbonate for rubber industry is usually packed in kraft paper bags which are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for calcium carbonate manufacturers. These bags together with the materials contained can be direct put into an internal mixer because they can easily melt and fully disperse in the rubber compounds as an effective ingredient. Different melting points (65-110 degree Celsius) are available for different using conditions.

BENEFITS:

- No fly loss of materials

- Improve packing efficiency

- Easy piling up and handling of materials

- Assure accurate adding of materials

- Cleaner work environment

- No need for disposal of packaging waste

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

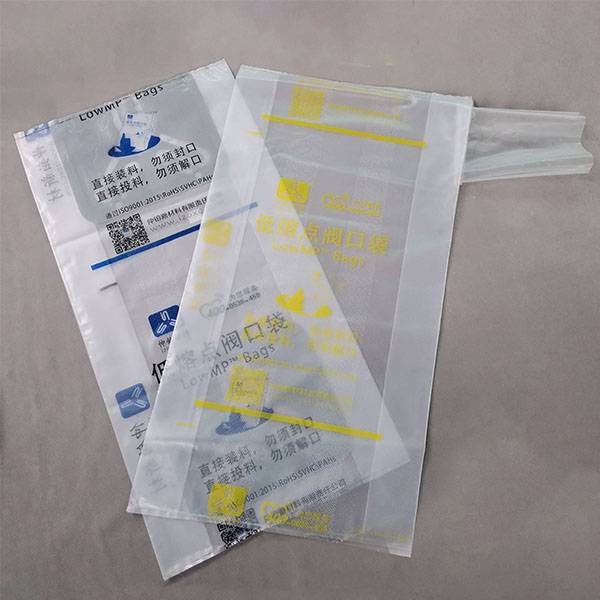

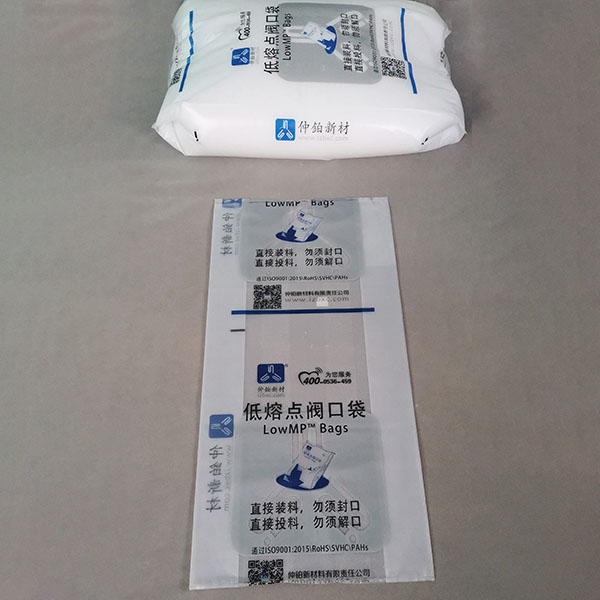

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Manufactur standard Batch Inclusion Bags For Silica - Low Melt Valve Bags for Calcium Carbonate – Zonpak, The product will supply to all over the world, such as: Oman , Norwegian , Iceland , We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.