Manufactur standard EVA Bag Roll - Batch Inclusion Bags – Zonpak

Manufactur standard EVA Bag Roll - Batch Inclusion Bags – Zonpak Detail:

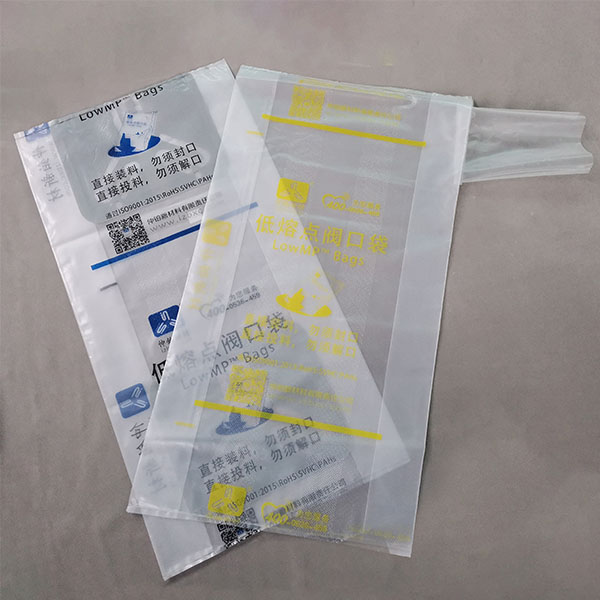

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into a mixer. The bags can easily melt and fully disperse into the rubber as a minor ingredient.

Using batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and increase work efficiency. Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Manufactur standard EVA Bag Roll - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: Korea , California , Greenland , We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!