New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags for Rubber Additives – Zonpak

New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags for Rubber Additives – Zonpak Detail:

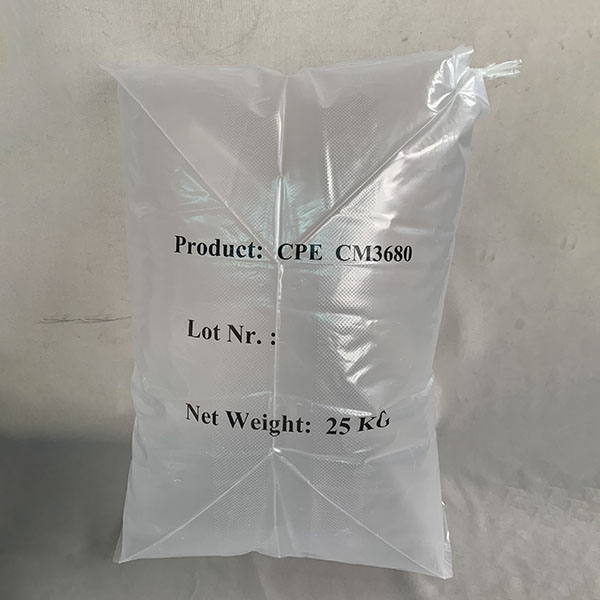

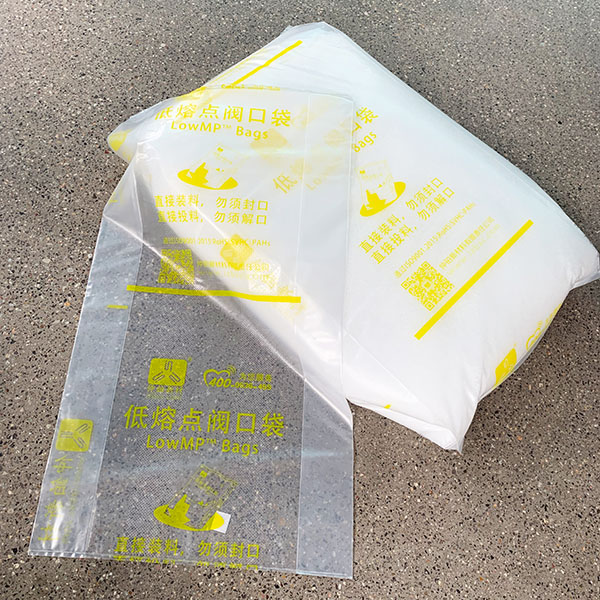

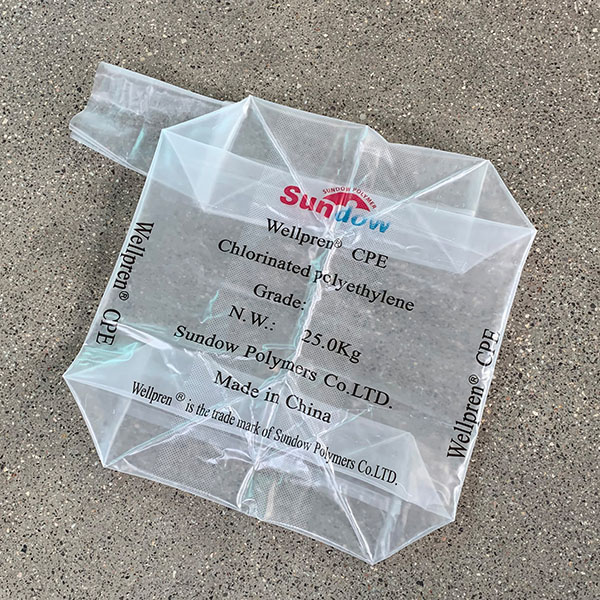

Rubber additives in form of powder or granule include carbon black, white carbon black, zinc oxide, and calcium carbonate are usually packed in kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for rubber additives manufacturers. These bags together with the materials contained can be direct put into an internal mixer because they can easily melt and fully disperse into the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different application conditions.

BENEFITS:

- No fly loss of materials

- Improve packing efficiency

- Easy piling up and handling of materials

- Assure accurate adding of materials

- Cleaner work environment

- No need for disposal of packaging waste

APPLICATIONS:

- rubber, CPE, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay, rubber process oil

OPTIONS:

Bag size, color, embossing, venting, printing

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags for Rubber Additives – Zonpak, The product will supply to all over the world, such as: Luxembourg , Hungary , Jamaica , Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.