OEM Factory for Flexible Packaging Film - Low Melt FFS Packaging Film – Zonpak

OEM Factory for Flexible Packaging Film - Low Melt FFS Packaging Film – Zonpak Detail:

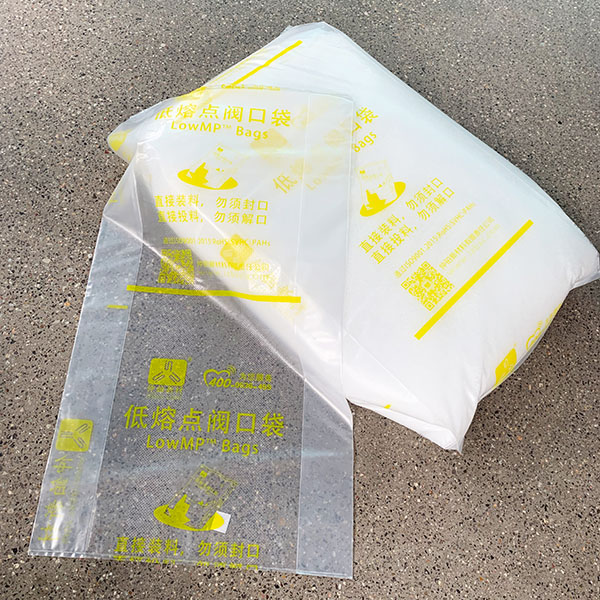

Low melt FFS packaging film is specially designed for the packaging of rubber chemicals on a form-fill-seal machine. The best feature of the film is its low melting point and good compatibility with natural and synthetic rubber. The bags made with the film on FFS machine can be direct put into an internal mixer during rubber or plastic mixing process. The bags can easily melt and fully disperse into the rubber compounds as a minor ingredient.

The film has stable chemical properties, can fit most rubber chemicals. Good physical strength makes the film suit most automatic FFS packing machines. Films with different melting points and thickness are available for different using conditions.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

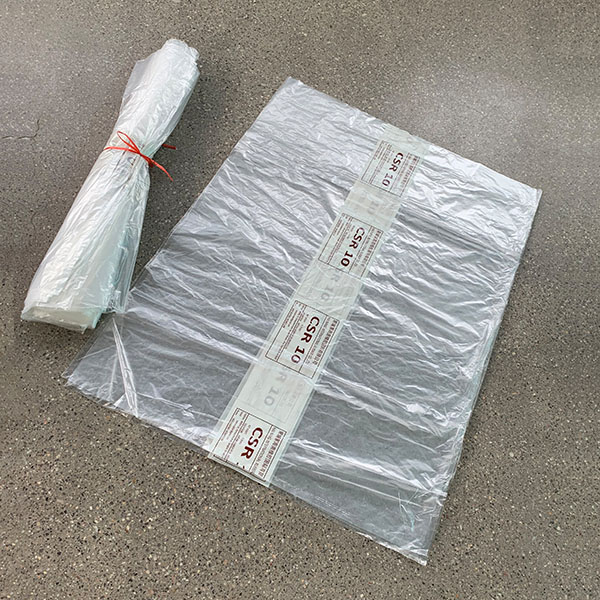

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for OEM Factory for Flexible Packaging Film - Low Melt FFS Packaging Film – Zonpak, The product will supply to all over the world, such as: Danish , Jamaica , Slovakia , Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

A good manufacturers, we have cooperated twice, good quality and good service attitude.