OEM Factory for Low Melt Valve Bags For Nano Kaolinite Clay - Low Melt Valve Bags for Zinc Oxide – Zonpak

OEM Factory for Low Melt Valve Bags For Nano Kaolinite Clay - Low Melt Valve Bags for Zinc Oxide – Zonpak Detail:

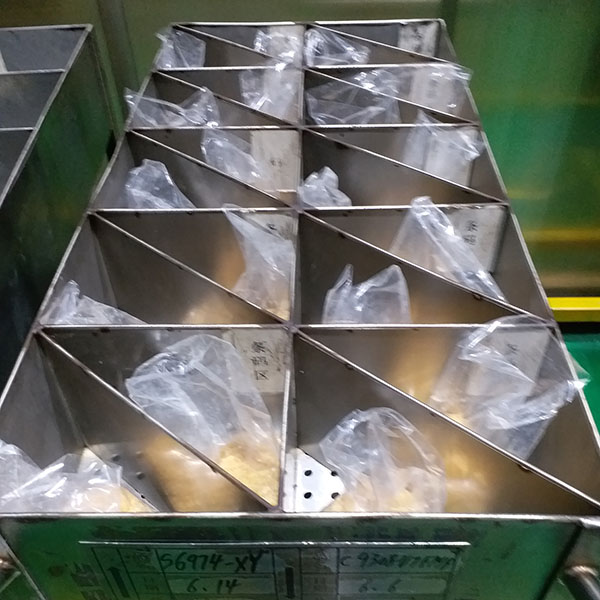

Zinc oxide for rubber industry is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for zinc oxide manufacturers. These bags of zinc oxide can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available as required.

Using the valve bags can avoid the fly loss of the material when packing and there is no need to seal, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

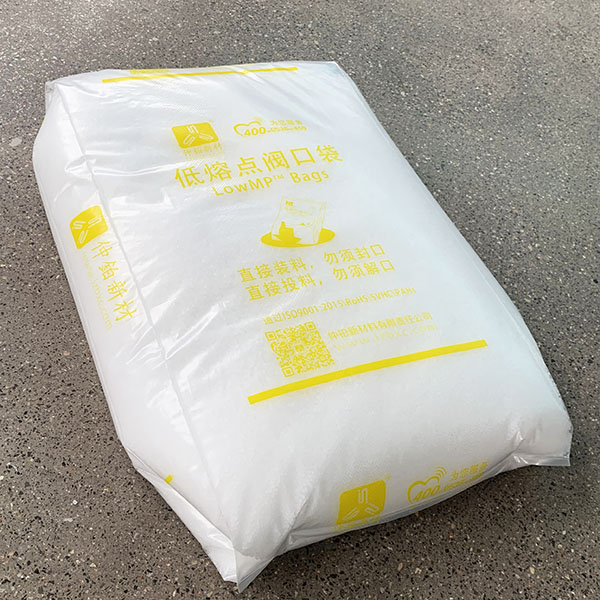

- Bag size: 5kg, 10kg, 20kg, 25kg

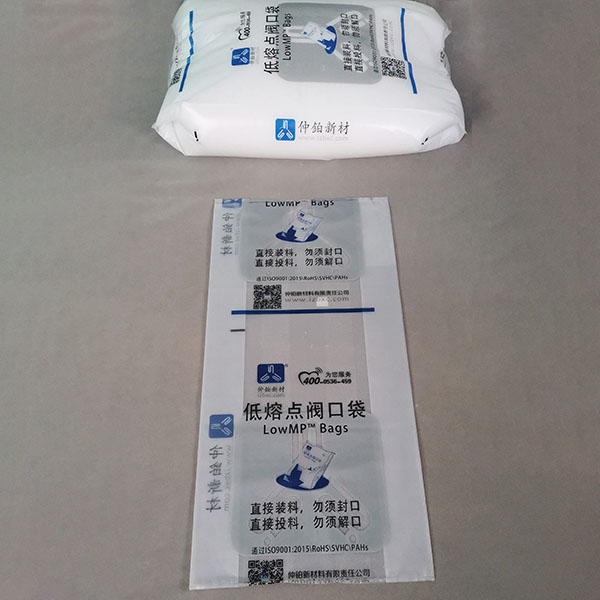

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for OEM Factory for Low Melt Valve Bags For Nano Kaolinite Clay - Low Melt Valve Bags for Zinc Oxide – Zonpak, The product will supply to all over the world, such as: Brasilia , Wellington , Anguilla , Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.