OEM Manufacturer EVA Bags for rubber - Low Melt Bags for Plastic Compounding – Zonpak

OEM Manufacturer EVA Bags for rubber - Low Melt Bags for Plastic Compounding – Zonpak Detail:

ZonpakTM low melt bags are used to pack compounding ingredients (e.g. process oil and powder additives) in plastic compounding and mixing process. Due to the property of low melting point and good compatibility with plastics, the bags together with the packed additives and chemicals can be direct put into a mixer, so it can provide cleaner work environment and accurate adding of additives. Using the bags can help plants get uniform compounds while saving additives and time.

Melting point, size and color can be customized according to the customer’s specific application requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

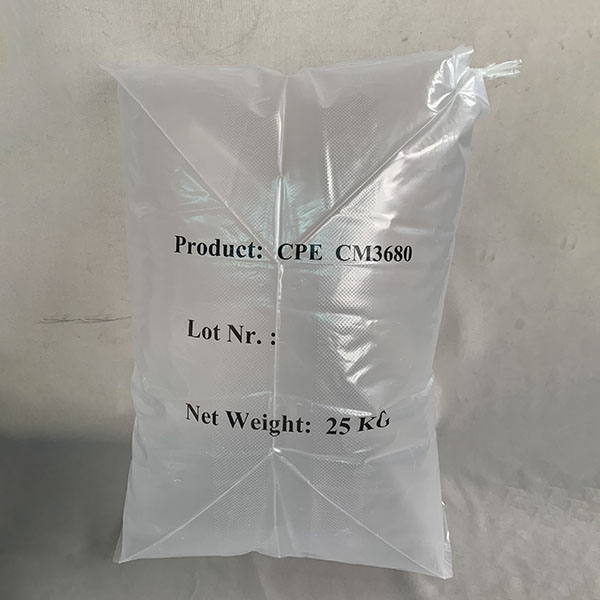

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for OEM Manufacturer EVA Bags for rubber - Low Melt Bags for Plastic Compounding – Zonpak, The product will supply to all over the world, such as: Bhutan , Comoros , Hungary , By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.