OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - EVA Plastic Valve Bags – Zonpak

OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - EVA Plastic Valve Bags – Zonpak Detail:

High speed and clean filling, no fly loss or spill

Self-sealing valve, no need for sewing or hot sealing

Direct put into a rubber mixer, no need for unpacking

Customized melting point and bag size

The above benefits make EVA plastic valve bags an ideal packaging for rubber chemicals. The bags bring convenience and high efficiency to both material suppliers and users.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

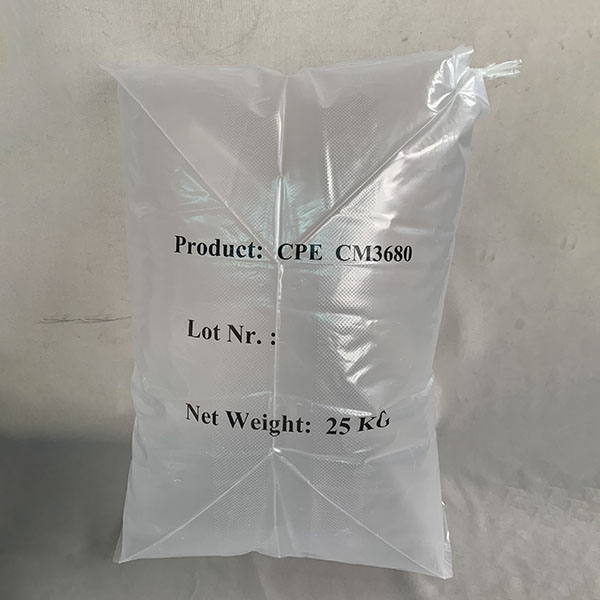

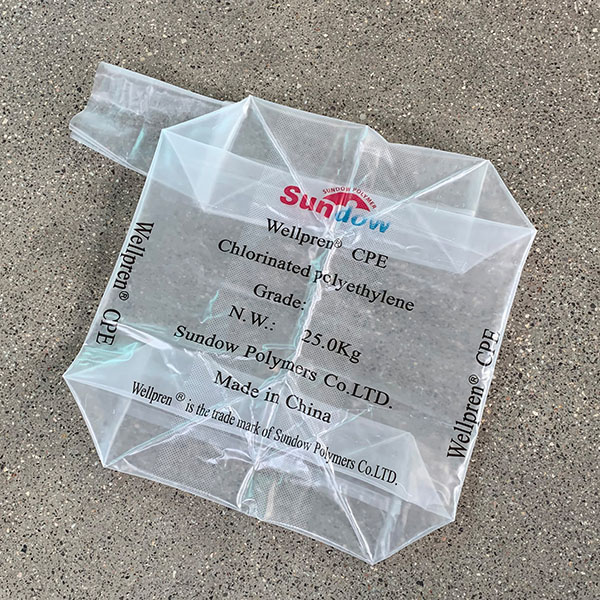

Product detail pictures:

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - EVA Plastic Valve Bags – Zonpak, The product will supply to all over the world, such as: Estonia , Macedonia , Cyprus , With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.