OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - Low Melt Valve Bags for Zinc Oxide – Zonpak

OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - Low Melt Valve Bags for Zinc Oxide – Zonpak Detail:

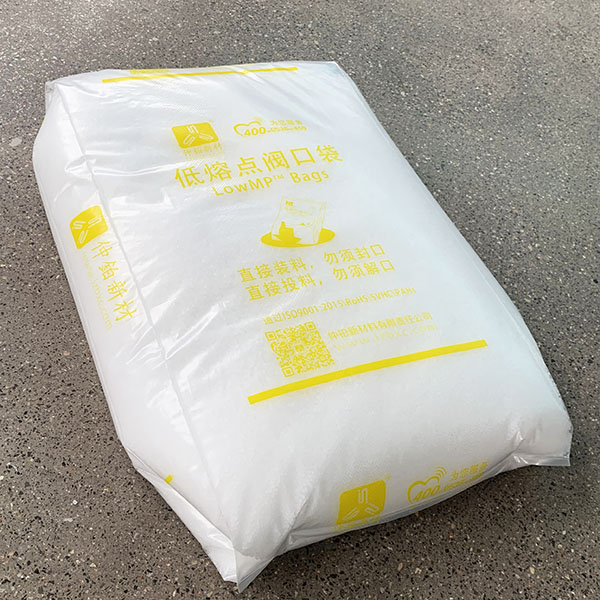

Zinc oxide for rubber industry is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for zinc oxide manufacturers. These bags of zinc oxide can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different using conditions.

Using the valve bags can avoid the fly loss of the material when packing and there is no need to seal, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1200 mm

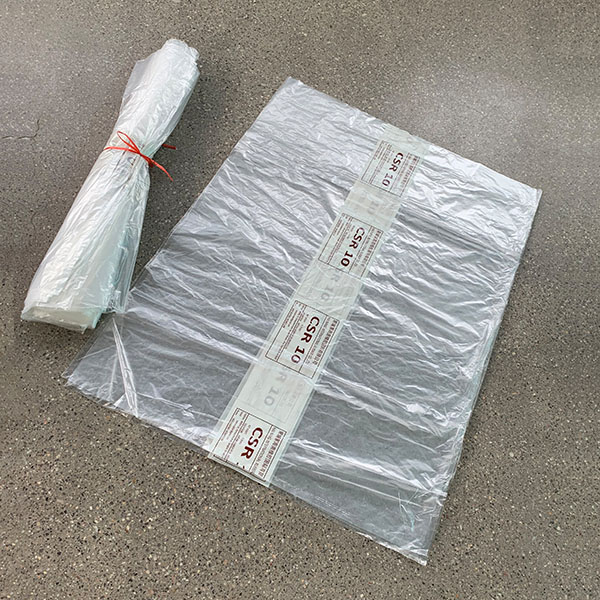

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for OEM manufacturer Low Melt Valve Bags For Rubber And Plastic Additives - Low Melt Valve Bags for Zinc Oxide – Zonpak, The product will supply to all over the world, such as: Barcelona , Dubai , Sydney , With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our goods, make sure you contact us now. We're looking forward to hearing from you soon.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.