OEM Manufacturer Low Melt Valve Bags For Zinc Oxide - Batch Inclusion Valve Bags for Silica – Zonpak

OEM Manufacturer Low Melt Valve Bags For Zinc Oxide - Batch Inclusion Valve Bags for Silica – Zonpak Detail:

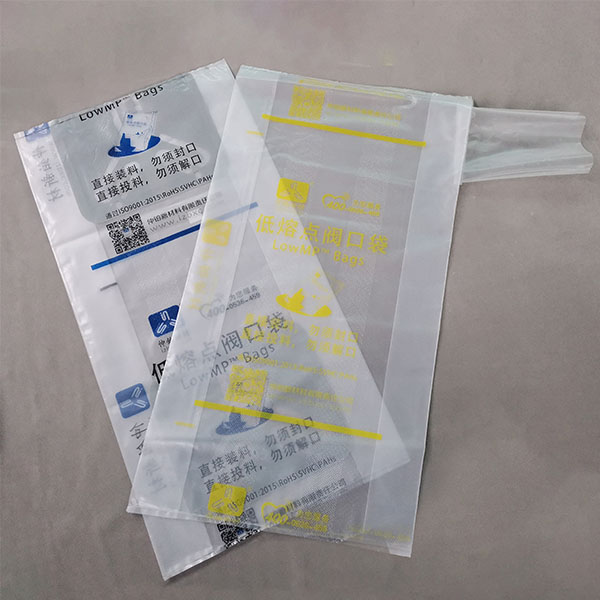

Silica for rubber industry (also called white carbon black) is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for silica manufacturers. These bags can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different using conditions.

BENEFITS:

- No fly loss of materials

- High speed packaging

- Easy piling up and handling of materials

- Accurate adding of materials

- Cleaner mixing area

- No need for disposal of packaging waste

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1200 mm

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for OEM Manufacturer Low Melt Valve Bags For Zinc Oxide - Batch Inclusion Valve Bags for Silica – Zonpak, The product will supply to all over the world, such as: Portugal , Canberra , Belgium , So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.