OEM/ODM Factory EVA Packing Bags - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak

OEM/ODM Factory EVA Packing Bags - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak Detail:

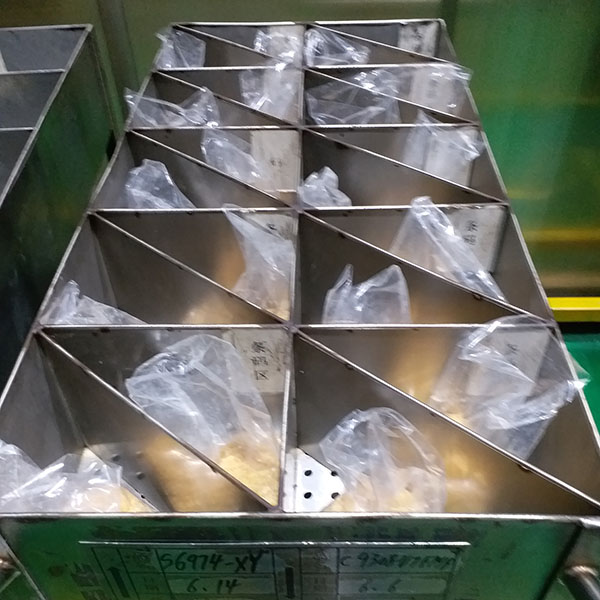

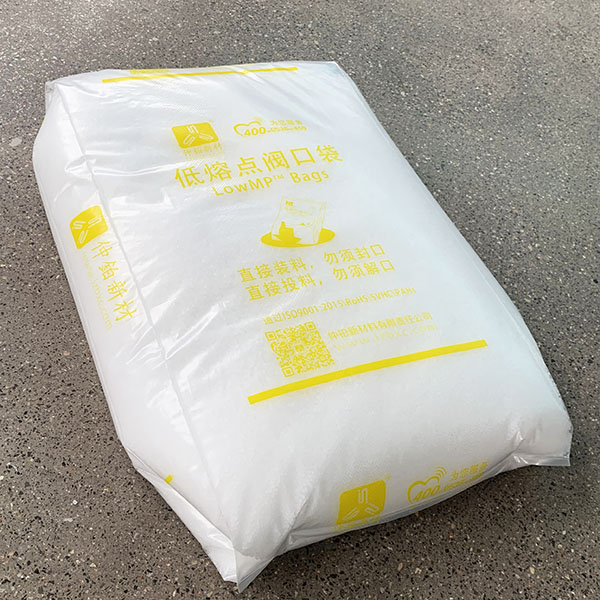

Rubber sealants and shock absorbers are widely used in the automotive industry, and rubber mixing process plays an important role in the production of rubber sealants and shock absorbers. ZonpakTM low melt bags (also called batch inclusion bags) are specially designed packaging bags for rubber ingredients and chemicals used in the rubber compounding and mixing process to improve the batch uniformity. The bags together with the materials contained can be direct put into a mixer, and the bags can easily melt and disperse into the compounds as a minor ingredient.

BENEFITS:

- Ensure accurate adding of ingredients and chemicals.

- Eliminate fly loss and spill of materials.

- Keep the mixing area clean.

- Save time and increase production efficiency.

- Bag size and color can be customized as required.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for OEM/ODM Factory EVA Packing Bags - Low Melt Bags for Rubber Seals and Shock Absorber Industry – Zonpak, The product will supply to all over the world, such as: Mombasa , Madagascar , Panama , In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!