One of Hottest for Valve Bag Filling Equipment - Low Melt Valve Bags for Zinc Oxide – Zonpak

One of Hottest for Valve Bag Filling Equipment - Low Melt Valve Bags for Zinc Oxide – Zonpak Detail:

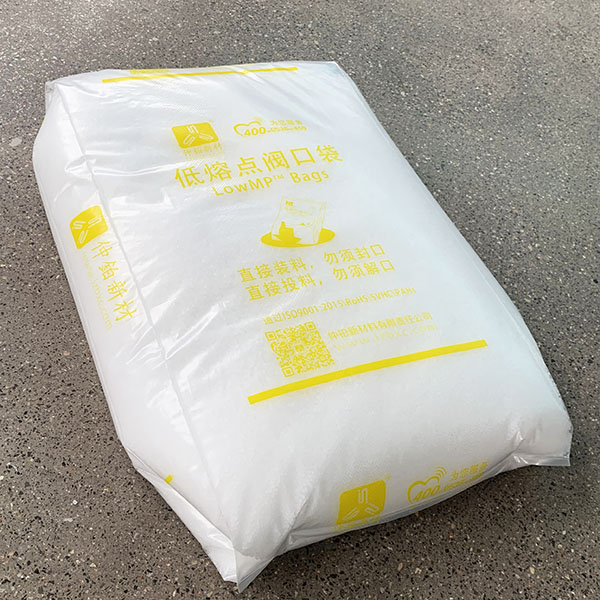

Zinc oxide for rubber industry is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for zinc oxide manufacturers. These bags of zinc oxide can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available as required.

Using the valve bags can avoid the fly loss of the material when packing and there is no need to seal, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for One of Hottest for Valve Bag Filling Equipment - Low Melt Valve Bags for Zinc Oxide – Zonpak, The product will supply to all over the world, such as: Jamaica , Costa rica , Bulgaria , When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.