Professional China Batch Inclusion FFS Film - EVA Packaging Film for Rubber Chemicals – Zonpak

Professional China Batch Inclusion FFS Film - EVA Packaging Film for Rubber Chemicals – Zonpak Detail:

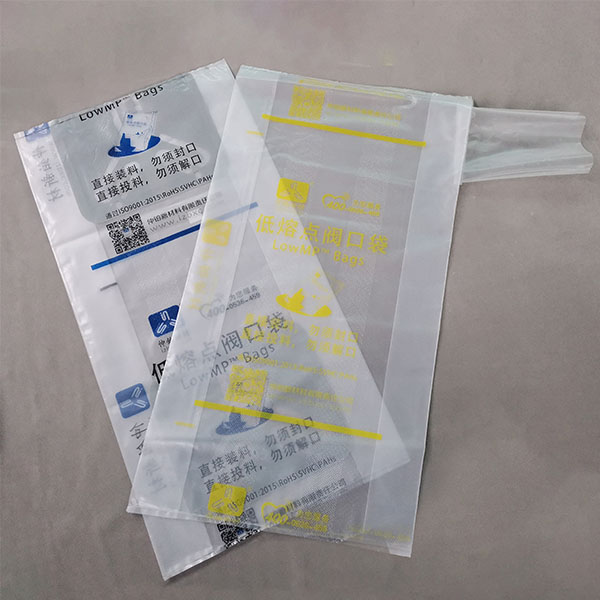

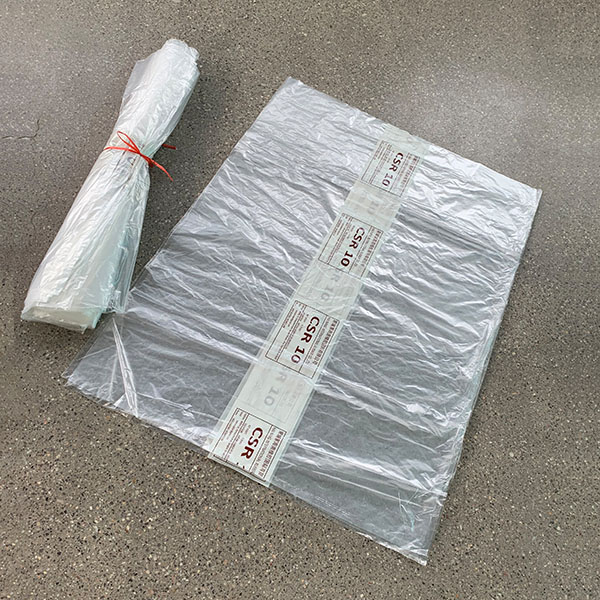

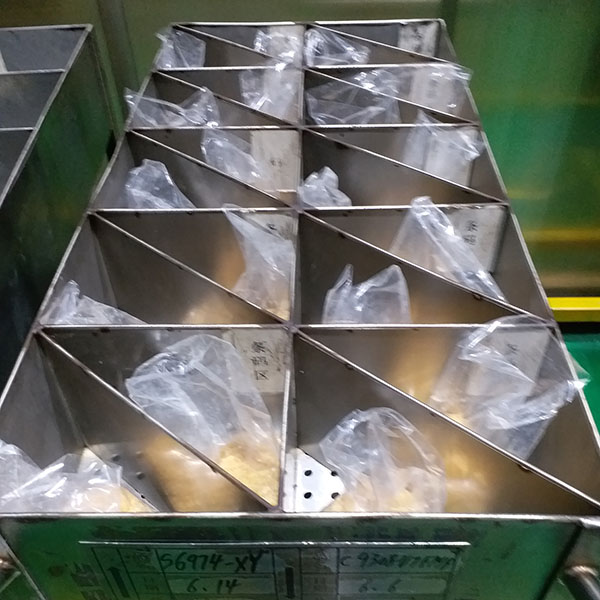

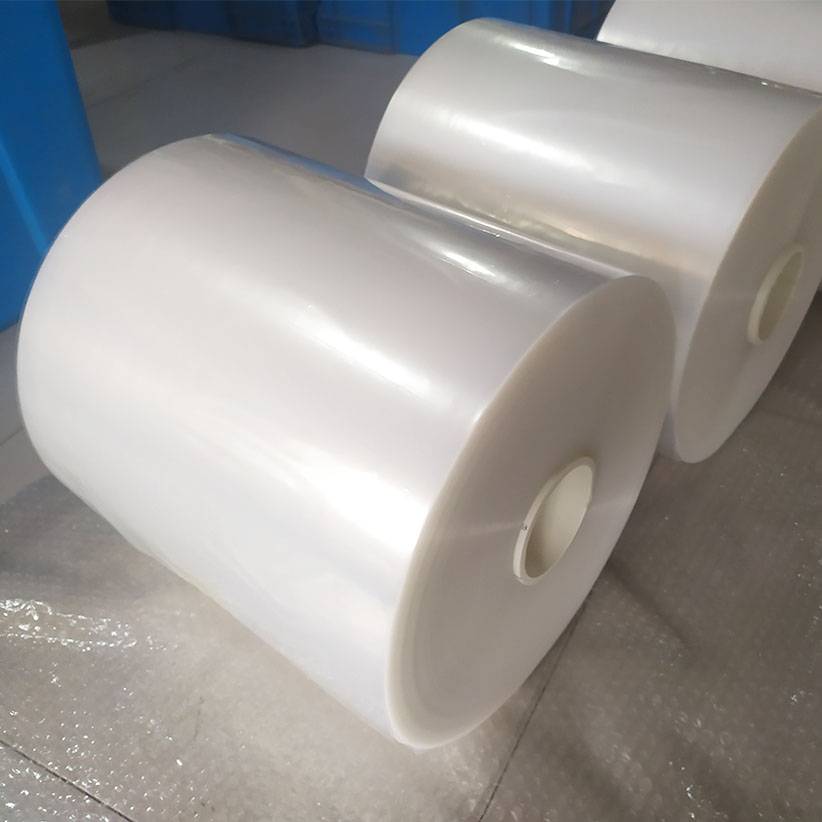

Rubber chemicals (e.g. rubber peptizer, anti-aging agent, curing agent, cure accelerator, aromatic hydrocarbon oil) are usually supplied to the rubber product plants in 20kg or 25kg or even larger packages, while only little amount of these materials are needed for each batch in the production. Thus the material users have to repeatedly open and seal the packages, which can cause material waste and contamination. To solve this problem, low melt EVA film is developed for the rubber chemical manufacturers to make little bags of rubber chemicals (e.g. 100g-5000g) with the automatic form-fill-seal (FFS) bagging machine. The film has a specific lower melting point and good compatibility with rubber or resin materials. So the bags together with the materials contained can be direct thrown into a banbury mixer, and the bags will melt and disperse into the rubber compound as a minor ingredient.

APPLICATIONS:

- peptizer, anti-aging agent, curing agent, rubber process oil

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Professional China Batch Inclusion FFS Film - EVA Packaging Film for Rubber Chemicals – Zonpak, The product will supply to all over the world, such as: Borussia Dortmund , Thailand , UAE , To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.