Renewable Design for Low Melt Batch Inclusion Bags - Batch Inclusion Valve Bags for Silica – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - Batch Inclusion Valve Bags for Silica – Zonpak Detail:

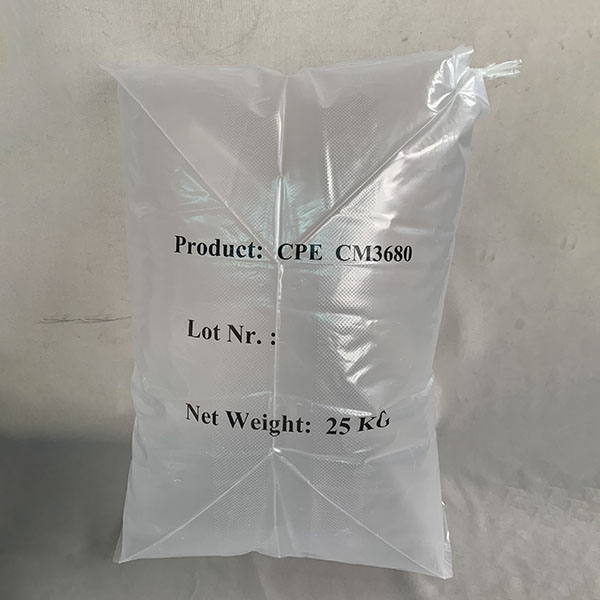

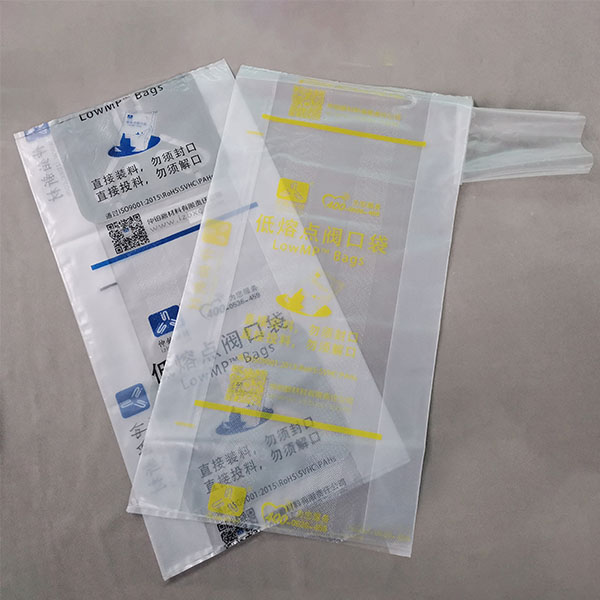

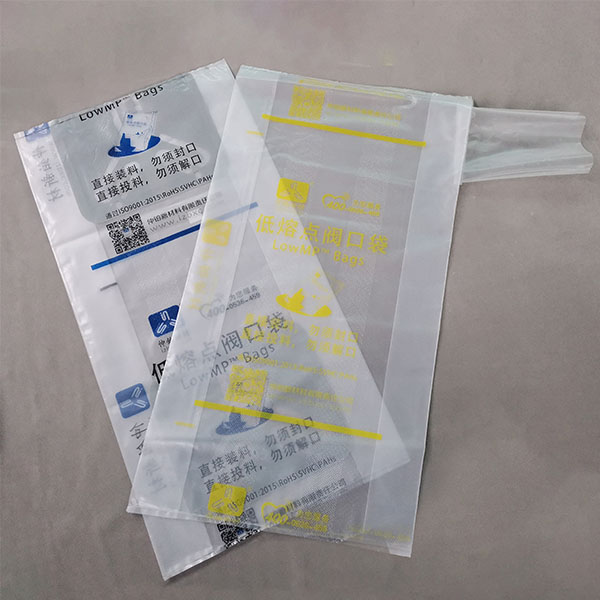

Silica for rubber industry (also called white carbon black) is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for silica manufacturers. These bags can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different using conditions.

BENEFITS:

- No fly loss of materials

- High speed packaging

- Easy piling up and handling of materials

- Accurate adding of materials

- Cleaner mixing area

- No need for disposal of packaging waste

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1200 mm

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Renewable Design for Low Melt Batch Inclusion Bags - Batch Inclusion Valve Bags for Silica – Zonpak, The product will supply to all over the world, such as: Manila , Ottawa , Germany , To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our goods list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're going to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.