Renewable Design for Low Melt Batch Inclusion Bags - Block Bottom EVA Valve Bags – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - Block Bottom EVA Valve Bags – Zonpak Detail:

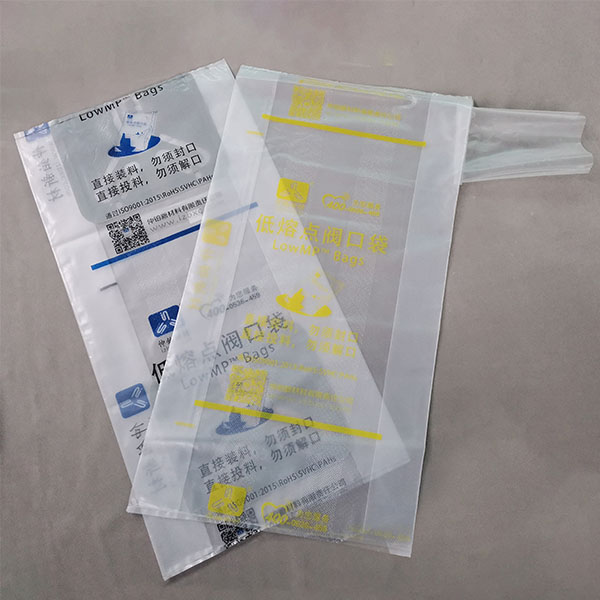

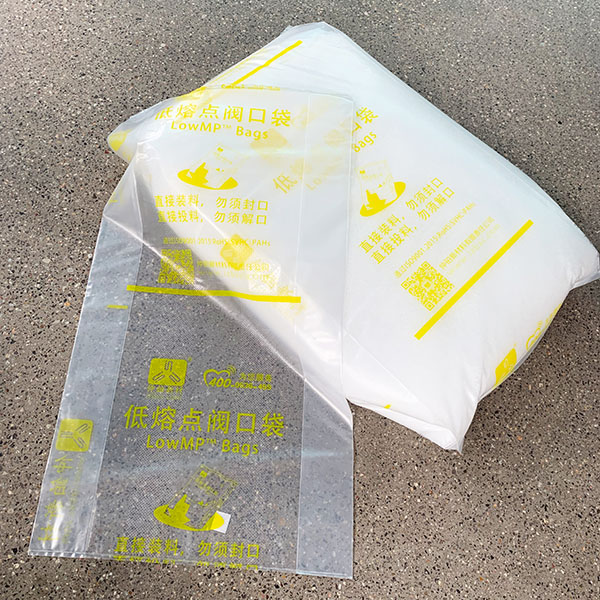

This kind of block bottom valve bag is specially designed for powder or pellets of rubber additives e.g. carbon black, silica, zinc oxide. The usual bag size include 5kg, 10kg, 20kg and 25kg. Melting point of the bag can be customized according to the application requirement. These bags together with the contained materials can be direct put into the mixing machine during rubber compounding process. It can help make the material user’s work easy and efficient. So more and more additive manufacturers and suppliers are replacing their paper bags with this EVA bags.

The bag dimensions can be customised as required. Anti-slip embossing, micro perforation and printing are all available if needed.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Renewable Design for Low Melt Batch Inclusion Bags - Block Bottom EVA Valve Bags – Zonpak, The product will supply to all over the world, such as: Mexico , Senegal , Algeria , We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.