Renewable Design for Low Melt Batch Inclusion Bags - EVA Batch Inclusion Valve Bags – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - EVA Batch Inclusion Valve Bags – Zonpak Detail:

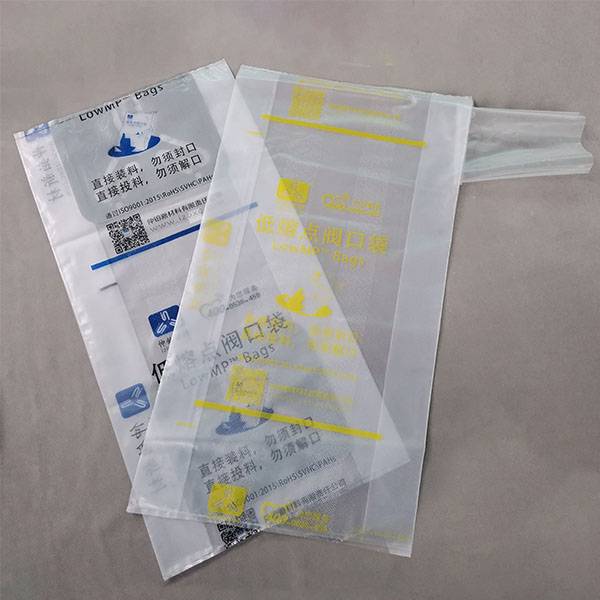

Zonpak™ low melt EVA valve bag is a special packaging bag for rubber chemicals. Comparing to the common PE or paper bags, the EVA bags are easier and cleaner to use for the rubber compounding process. High speed and quantitative filling can be achieved by placing the valve port on the top of the bag to the spout of the filling machine . Different valve types are available to match different filling machines and materials.

The valve bag is made of virgin EVA, featured with low melting point, good compatibility with rubber, solid and high impact resistance. After filled the bag become a flat cuboid, can be piled up neatly. It is suitable for the packing of various particles, powders, and ultra-fine powders.

CHARACTERISTICS:

1. Low Melting Points

Bags with different melting points (72-110ºC) are available as required.

2. Good Dispersity and Compatibility

The bags can be used in various rubber and plastic materials.

3. High Physical Strength

The bags are applicable to most filling machines.

4. Good Chemical Stability

Good environmental stress cracking resistance and weather resistance help ensure safer material storage.

5. Special Design

Embossing, venting and printing are all available.

APPLICATIONS:

Various bag size (5kg, 10kg, 20kg, 25kg) are available for particle and powder materials (e.g. carbon black, white carbon black, zinc oxide, calcium carbonate).

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Renewable Design for Low Melt Batch Inclusion Bags - EVA Batch Inclusion Valve Bags – Zonpak, The product will supply to all over the world, such as: Albania , Portugal , Libya , As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.