Renewable Design for Low Melt Batch Inclusion Bags - Low Melt EVA Bags for Carbon Black – Zonpak

Renewable Design for Low Melt Batch Inclusion Bags - Low Melt EVA Bags for Carbon Black – Zonpak Detail:

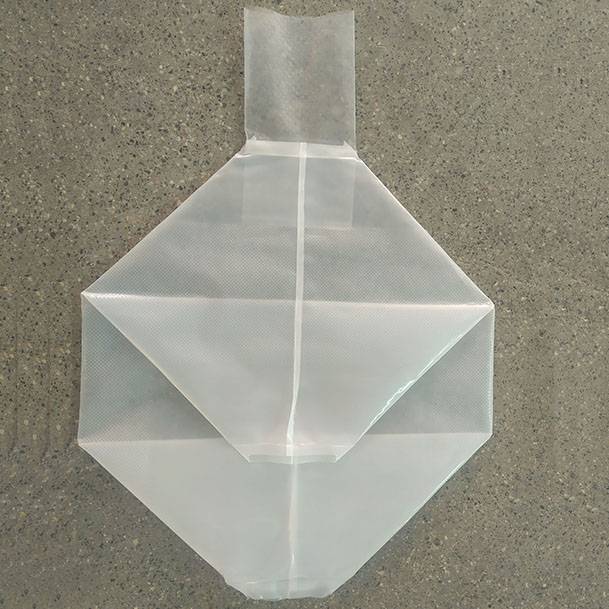

This kind of EVA bag is a specially designed for rubber additive Carbon Black. With these low melt valve bags, carbon black manufacturers or suppliers can make little uniform packages of 5kg, 10kg, 20kg and 25kg to meet the users demand. Compared to the traditional paper bag, it is easier and cleaner to use for the rubber compounding process.

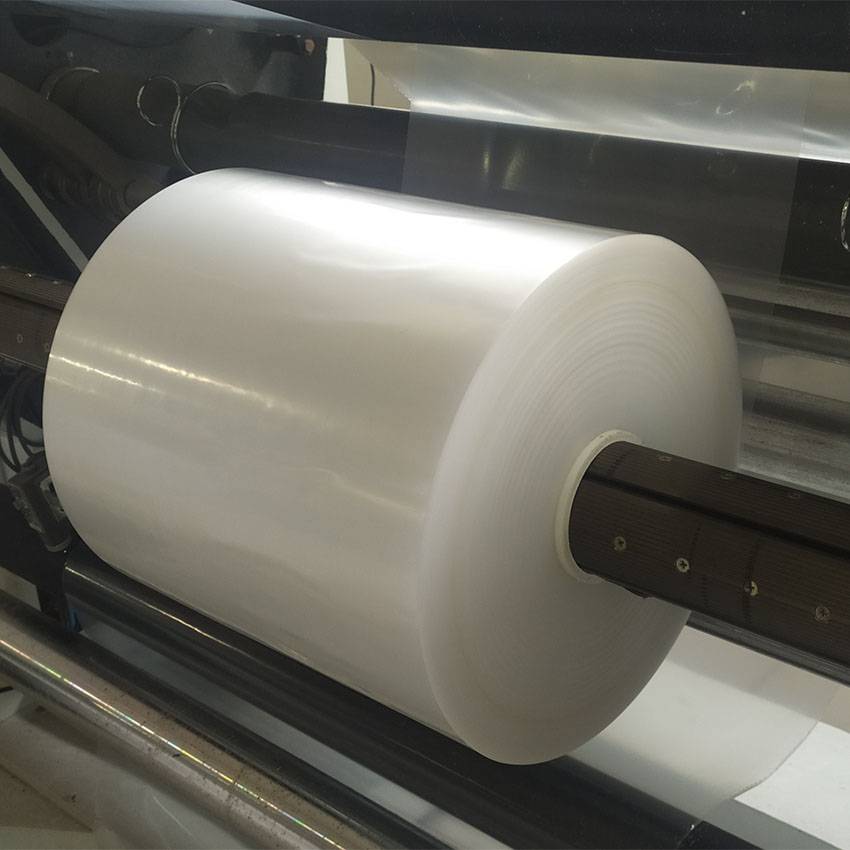

The valve bags are made from EVA resin (copolymer of ethylene and vinyl acetate) which has particualr low melting point and good compatibility with rubber, so the bags together with the carbon black packed inside can be direct thrown into a banbury mixer during rubber mixing process, and the bags can fully disperse in the compounds as a minor ingredient.

Options:

Gusset or block bottom, Internal or external valve, embossing, venting, colour, printing

Specification:

Melting point available: from 80 to 100 deg. C

Material: virgin EVA

Film thickness: 100-200 micron

Bag size: 5kg, 10kg, 20kg, 25kg

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Renewable Design for Low Melt Batch Inclusion Bags - Low Melt EVA Bags for Carbon Black – Zonpak, The product will supply to all over the world, such as: Bangladesh , Albania , Bahamas , For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!