Top Suppliers Batch Inclusion Bags For Zinc Oxide - EVA Plastic Valve Bags – Zonpak

Top Suppliers Batch Inclusion Bags For Zinc Oxide - EVA Plastic Valve Bags – Zonpak Detail:

High speed and clean filling, no fly loss or spill

Self-sealing valve, no need for sewing or hot sealing

Direct put into a rubber mixer, no need for unpacking

Customized melting point and bag size

The above benefits make EVA plastic valve bags an ideal packaging for rubber chemicals. The bags bring convenience and high efficiency to both material suppliers and users.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

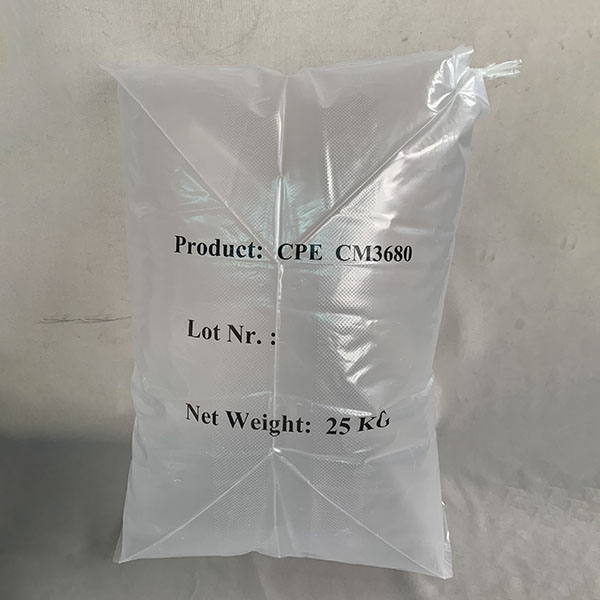

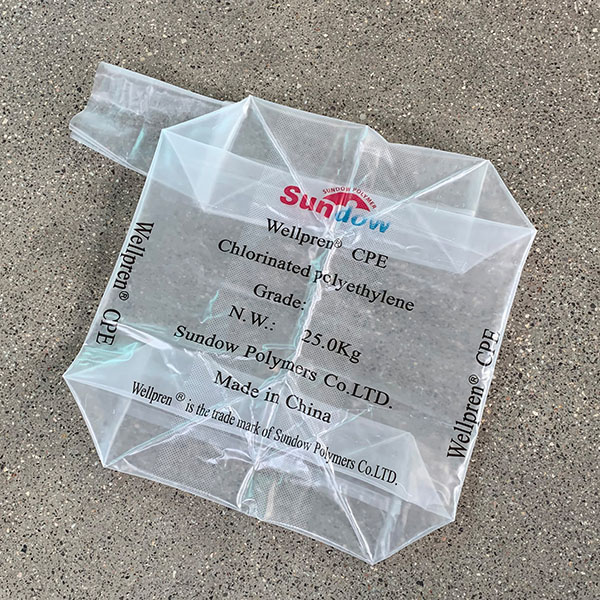

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Top Suppliers Batch Inclusion Bags For Zinc Oxide - EVA Plastic Valve Bags – Zonpak, The product will supply to all over the world, such as: Gabon , Uruguay , California , Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!