Top Suppliers Batch Inclusion Bags For Zinc Oxide - Low Melting Point Valve Bags – Zonpak

Top Suppliers Batch Inclusion Bags For Zinc Oxide - Low Melting Point Valve Bags – Zonpak Detail:

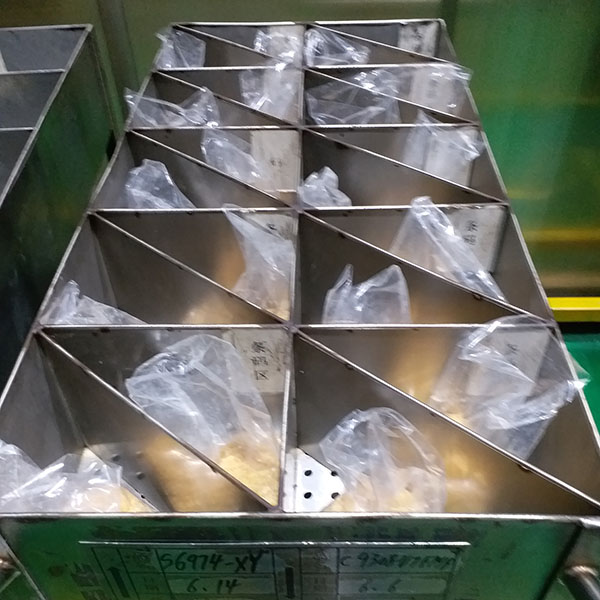

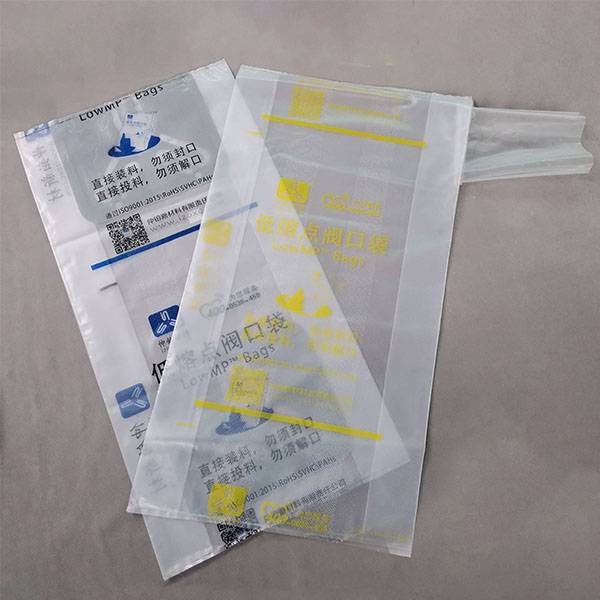

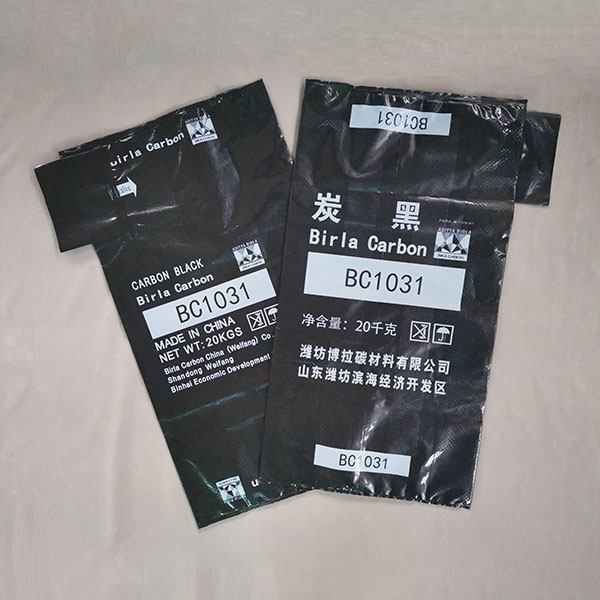

ZonpakTM low melting point valve bags are specially designed for the industrial packaging of rubber chemicals and resin pellets (e.g. carbon black, zinc oxide, silica, calcium carbonate, CPE). Using the low melting bags, material suppliers can make 5kg, 10kg, 20kg and 25kg packages which can be direct put into an internal mixer by the material users during rubber compounding process. The bags will melt and fully disperse into the rubber compounds as a minor ingredient.

BENEFITS:

- No fly loss of materials when packing.

- Improve the material packing efficiency.

- Facilitate the stacking and palletizing.

- Help material users reach accurate dosing of materials.

- Provide material users with cleaner work environment.

- Eliminate the disposal of packaging waste

SPECIFICATION:

- Melting point available: 70 to 110 deg. C

- Material: virgin EVA

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Top Suppliers Batch Inclusion Bags For Zinc Oxide - Low Melting Point Valve Bags – Zonpak, The product will supply to all over the world, such as: Mauritius , Armenia , Morocco , Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.