Top Suppliers Industrial EVA Bags - Batch Inclusion Bags – Zonpak

Top Suppliers Industrial EVA Bags - Batch Inclusion Bags – Zonpak Detail:

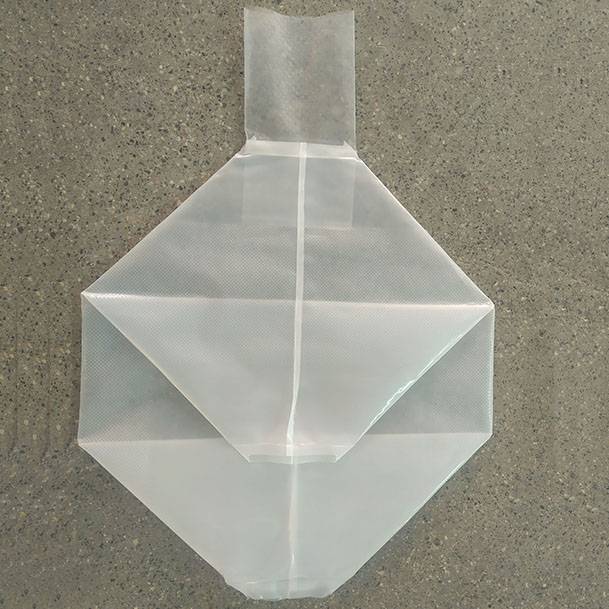

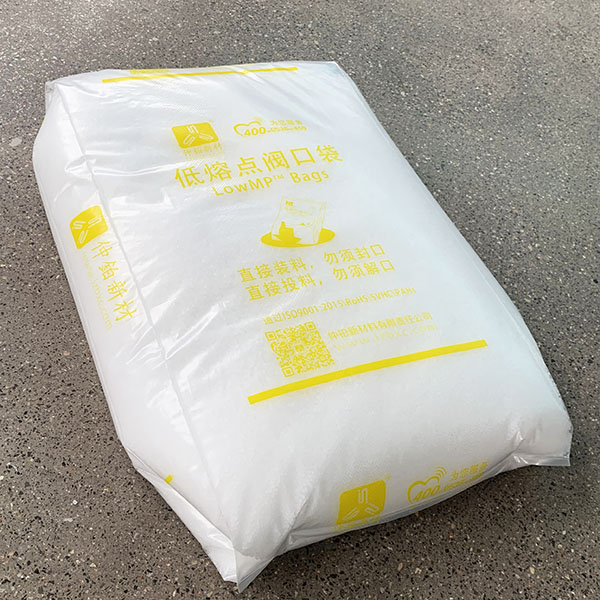

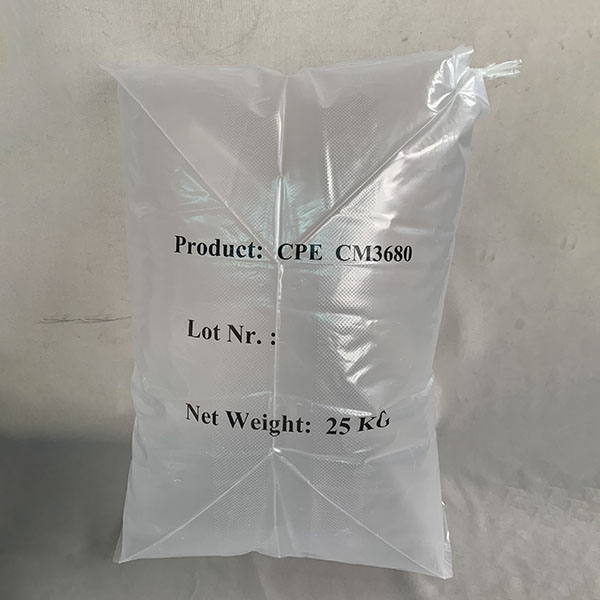

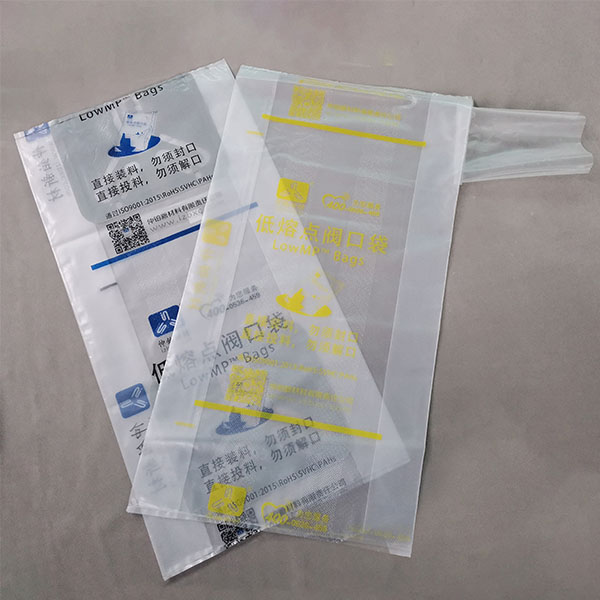

Batch inclusion bags are designed for packaging compounding ingredients in rubber or plastic mixing process to improve the batch uniformity. Bags with different melting points are suitable for different mixing conditions. Due to their low melting point and good compatibility with rubber, the bags together with the chemicals or additives inside can be direct put into a mixer. The bags can easily melt and fully disperse into the rubber as an effective ingredient. Using ZonpakTM batch inclusion bags can help rubber plants improve batch uniformity, provide cleaner work environment, save expensive additives, and raise efficiency.

Bags of different melting points, sizes, thickness, and colors are available to meet the customers’ requirement.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPaTD ≥16MPa |

| Elongation at break | MD ≥400%TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPaTD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Top Suppliers Industrial EVA Bags - Batch Inclusion Bags – Zonpak, The product will supply to all over the world, such as: United Arab emirates , Turkmenistan , Jordan , We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.