Trending Products Batch Inclusion Low Melt Bags – Low Melt EVA Valve Bags – Zonpak

Trending Products Batch Inclusion Low Melt Bags – Low Melt EVA Valve Bags – Zonpak Detail:

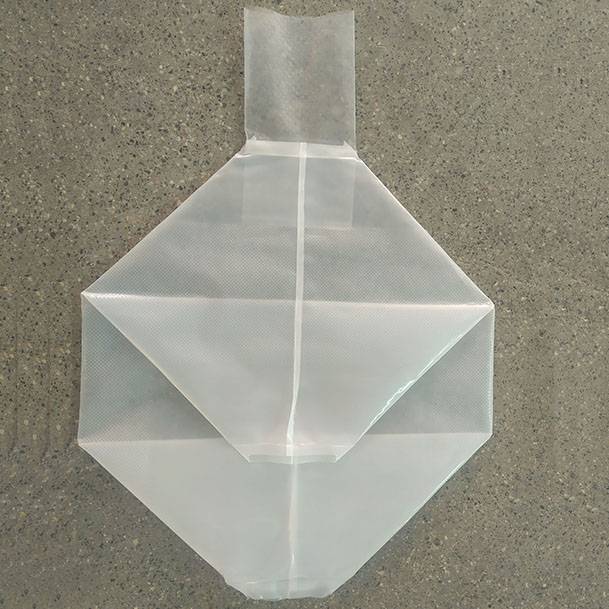

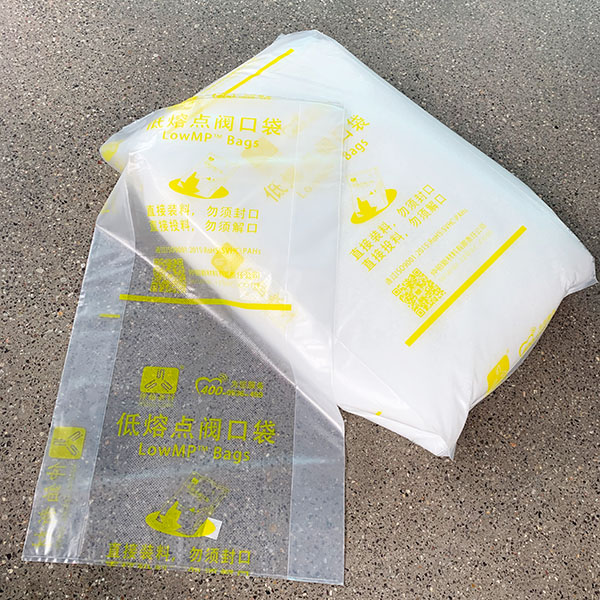

Low melt EVA valve bags are specially designed packaging bags for rubber additives and resin pellets. These bags are suitable for automatic filling machine. Pack the materials with low melt EVA valve bags, there is no need for sealing after filled and no need for unsealing before putting the bags of material into an internal mixer. So low melt EVA valve bags are ideal substitute for traditional kraft and PE heavy duty bags.

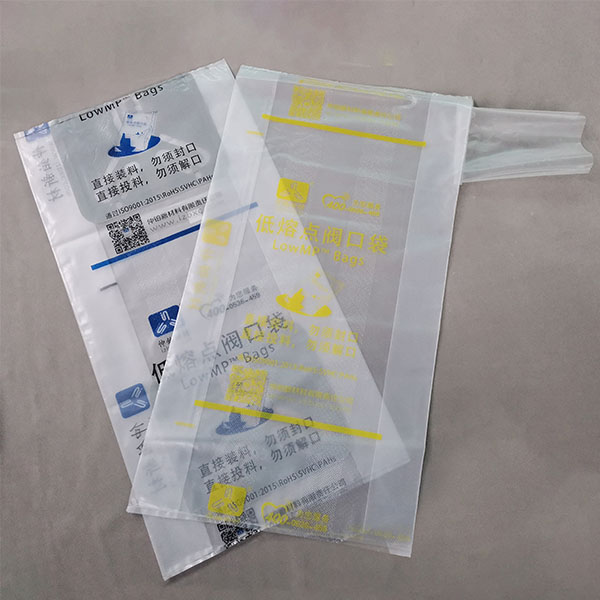

High speed and quantitative filling can be achieved by simply placing the valve port on the top or at bottom of the bag to the spout of a filling machine. Different types of valve are available to match different filling machines and materials. The valve bags are made of new materials, featured with low melting point, good compatibility with rubber, solid and high impact resistance. After filled the bag turns into a flat cuboid, can be piled up neatly. It is suitable for the packaging of various particle, powder, and ultra-fine powder materials.

PROPERTIES:

Bags with different melting points are available to meet customers’ particular requirement. They have good meltability and dispersity in the rubber and plastic, and are applicable to various filling machines.

The bags have excellent chemical stability, no toxicity, good environmental stress cracking resistance, weather resistance and compatibility with the rubber materials. The bags can melt in the rubber compound as a minor effective ingredient of the rubber formula. The bags can be compatibly blended with natural rubber, styrene butadiene rubber (SBR), butadiene rubber (BR), Solution polymerized butadiene styrene rubber (SSBR), polyisoprene rubber, high styrene resin and many other resins, without affecting the physical and chemical properties of the rubber compounds.

APPLICATIONS:

These bags are mainly used for big packages (10-25kg) of various particle and powder materials (e.g. CPE, carbon black, white carbon black, zinc oxide, calcium carbonate) in the rubber industry (tire, hose, tape, shoes), plastic processing industry (PVC, plastic pipe and extrude ) and rubber and plastic additives industry.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Trending Products Batch Inclusion Low Melt Bags – Low Melt EVA Valve Bags – Zonpak, The product will supply to all over the world, such as: Korea , Sri Lanka , Tanzania , We always hold on the company's principle "honest, professional, effective and innovation", and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!