Trending Products Batch Inclusion Low Melt Bags – Low Melt Valve Bags for Zinc Oxide – Zonpak

Trending Products Batch Inclusion Low Melt Bags – Low Melt Valve Bags for Zinc Oxide – Zonpak Detail:

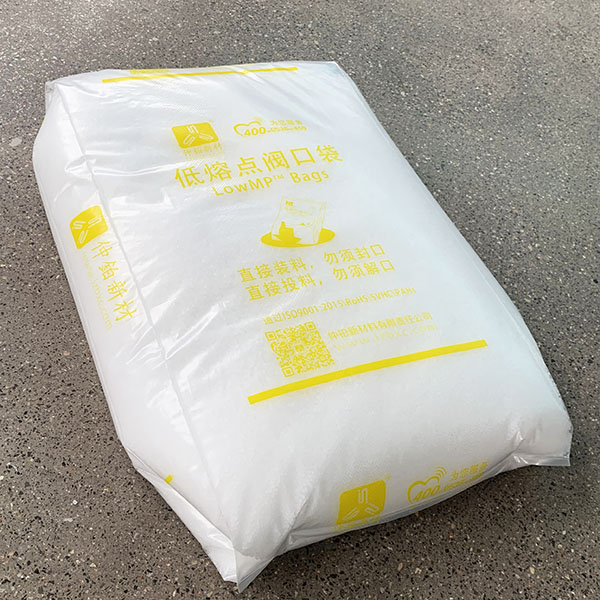

Zinc oxide for rubber industry is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for zinc oxide manufacturers. These bags of zinc oxide can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available as required.

Using the valve bags can avoid the fly loss of the material when packing and there is no need to seal, so it largely improves the packaging efficiency. With standard packages and no need for unpacking before using the materials, low melt valve bags also facilitate the work of the material users.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag size: 5kg, 10kg, 20kg, 25kg

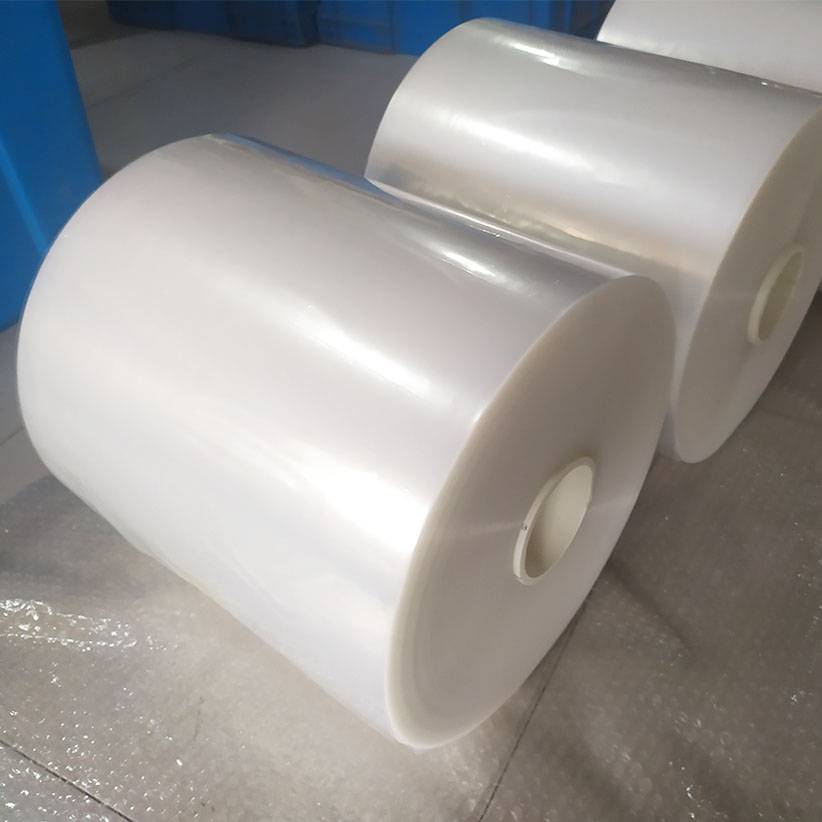

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Trending Products Batch Inclusion Low Melt Bags – Low Melt Valve Bags for Zinc Oxide – Zonpak, The product will supply to all over the world, such as: Nigeria , Armenia , Belize , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!